What are the benefits of outsourcing?

Outsourcing mechanical design can bring significant benefits to a company. One of the most important is cost savings. When a company decides to outsource mechanical design, it can avoid making large investments in developing its own resources, such as hiring staff or acquiring the latest technology. Specialist companies like Hefmec can provide these services at no extra cost, making outsourcing a financially sound choice for many companies.

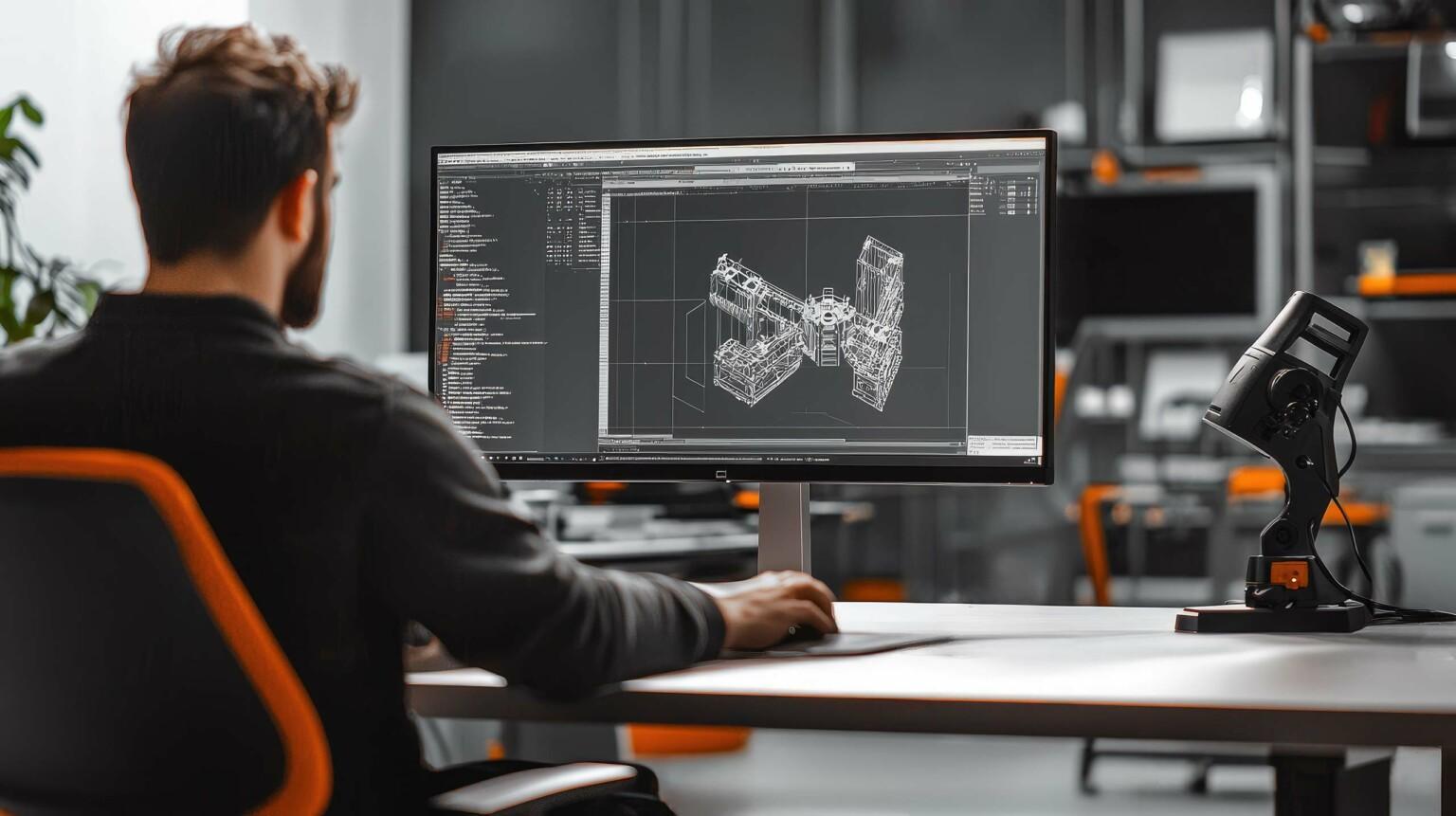

Efficiency is another important benefit of outsourcing. Hefmec’s experts use agile working methods and modern design software such as SolidWorks and CATIA, allowing for faster project implementation. When others talk about months, we talk about days. This means companies can speed up their product development processes and get products to market earlier, improving competitiveness.

In addition, outsourcing brings expertise to the company that may not be available in-house. Hefmec’s design team consists of experienced engineers and graduate engineers who combine practical experience with a strong theoretical background. Our diverse knowledge of different technologies and industries ensures that our solutions are technically right-sized and will continue to improve productivity in the future.

How to choose the right outsourcing partner?

Choosing the right partner to outsource your mechanical design is crucial to the success of your project. Firstly, the experience and references of the partner are important evaluation criteria. Years of experience and previous successful projects are a sign of reliability and competence. Hefmec has extensive experience in various projects, such as the design of robot geogrippers and vehicle components.

Technical capability is another key factor. The partner must master the latest design software and technologies in order to provide efficient and up-to-date solutions. Hefmec uses software such as SolidWorks and Creo, which enables the implementation of complex design tasks.

Communication skills and an open culture are also important. It is important that the partner is willing to listen to the client’s needs and understand the root causes of the problem. Hefmec is committed to a customer-centric approach, which ensures that our customers receive solutions that are tailored to their needs.

How does outsourcing affect the company’s operations?

Outsourcing can change the day-to-day operations of a company in many ways. First, it can free up internal resources for other critical tasks, such as product development or marketing. This can improve the company’s overall efficiency and focus on strategically important areas.

In terms of organisational culture, outsourcing can bring new ways of working and innovative ways of thinking. Hefmec’s agile working methods and expert team can inspire the company’s own employees and promote learning and development. This can lead to improved collaboration and more open communication throughout the organisation.

From a resource management perspective, outsourcing can help a company adapt to rapidly changing market situations. External partners such as Hefmec can provide the flexibility to respond quickly to new challenges and opportunities. This can improve a company’s ability to adapt and succeed in a competitive environment.

Hefmec offers comprehensive mechanical design services to meet the most demanding industrial production problems. Our experienced designers combine practical experience with theory and use state-of-the-art design software, ensuring that all projects are completed with high quality and efficiency. Read more about our services.