What are the testing steps in mechanical design?

Mechanical design is a multi-stage process in which testing plays a key role. The first stage is analysis, where the design team reviews the customer’s needs and defines the design objectives. During this phase, we identify problems and opportunities, laying the foundation for the entire design process.

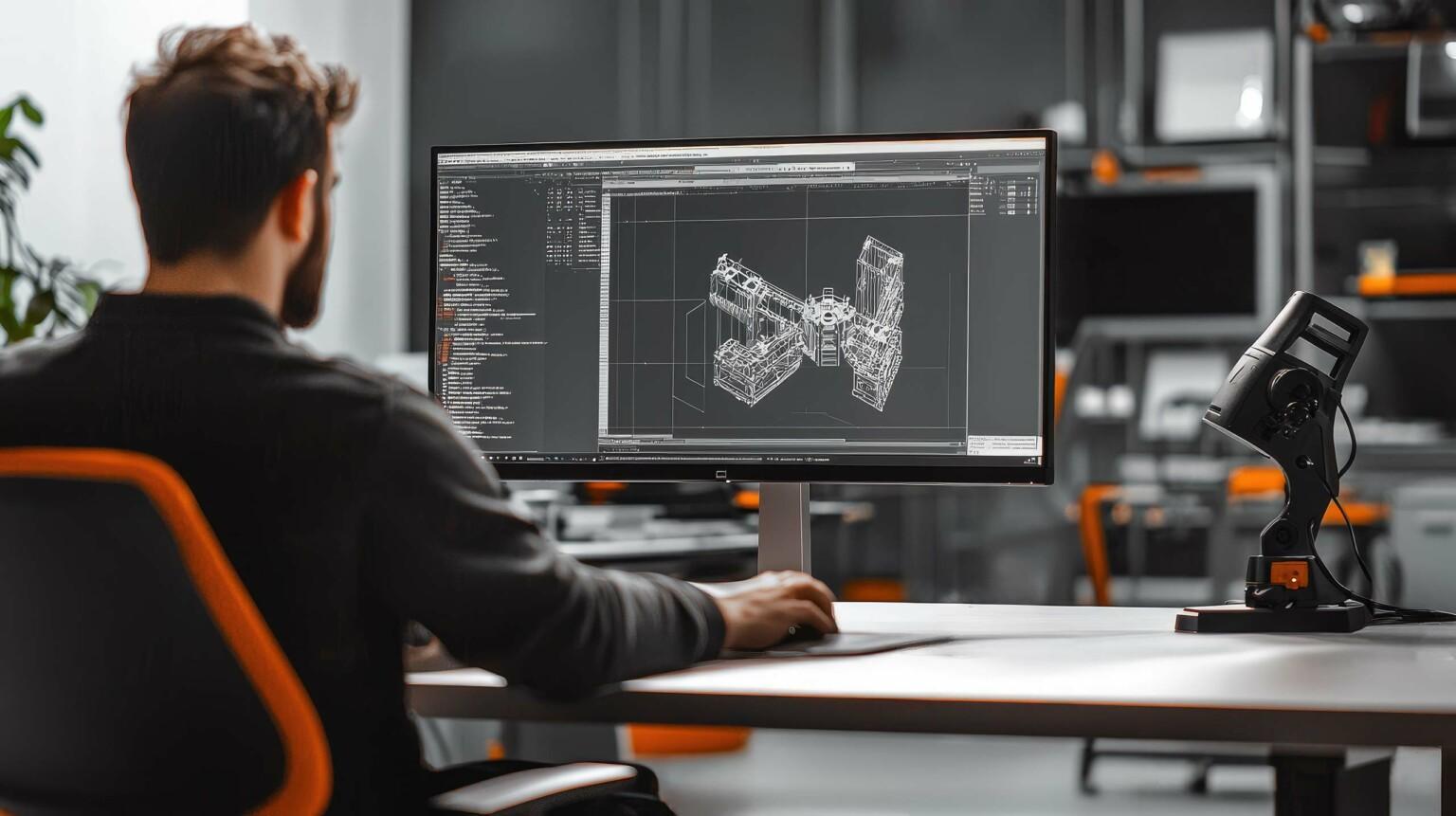

Next, we move on to simulation, where we use advanced software to model the performance of our design solutions. Simulation allows us to predict how the designed mechanism will behave in real-world conditions and make the necessary changes before actual prototyping.

Prototype testing is the next key step. In this phase, we produce physical prototypes that are carefully tested in real-life situations. Prototype testing provides valuable information on the performance of the design and helps identify potential areas for improvement.

The final stage is quality assurance, where we ensure that the product meets all the quality requirements. Our quality assurance process is thorough and ensures that the final product is both reliable and durable for our customers.

Why is testing important in mechanical design?

In mechanical design, testing is a critical part of the process as it minimises risk and improves product reliability. Without careful testing, the design process will be incomplete, which can lead to costly errors in the production phase. Testing allows us to ensure that the product works as designed and meets customer expectations.

Testing also helps to manage costs. By identifying and fixing potential problems at the design stage, we can avoid costly changes at a later stage. This makes the whole design process more efficient and cost-effective.

In addition, testing has a major impact on the success of the design and the product’s market entry. A well-tested product creates customer confidence and improves market position. Hefmec’s testing processes are designed to support the customer’s business objectives and contribute to their competitiveness.

How does simulation support the testing phases of mechanical design?

Simulation is an essential part of the testing phase of mechanical design, as it allows for the evaluation of designs before physical prototypes are produced. Simulation tools allow us to model the behaviour of designed components and systems under different loading and environmental conditions.

The advantage of simulation is that it provides a quick and cost-effective way to identify potential problems in the design. This reduces the need to produce multiple physical prototypes, saving both time and resources.

The simulation tools also allow you to test different scenarios, helping you to optimise your design solutions technically and economically. This makes the whole design process more agile and flexible, which is one of Hefmec’s competitive advantages.

What are the challenges of the testing phases?

There are many challenges associated with the testing phases of mechanical design. One of the most common is time pressure. Tight project schedules can put pressure on the thoroughness of the testing phases. However, it is important to allow sufficient time for testing to ensure product quality and functionality.

Budgetary constraints are another major challenge. Although testing can be expensive, it is essential for risk management. Budgetary constraints make it important to prioritise the most critical testing phases and use simulation to save resources.

Technical problems and unexpected challenges can also delay the testing process. To overcome these challenges, it is important to maintain an open and agile culture that enables rapid response and problem solving. Hefmec’s open and flexible way of working is designed to support effective problem solving and project management.

The testing stages of mechanical design are crucial to ensure product performance, quality and cost-effectiveness. Hefmec’s expert team is committed to providing customers with high-quality design solutions that are both technically advanced and economically sound. Take a closer look at our mechanical design services and let us help you achieve successful projects.