The importance of mechanical design

Mechanical design is a key enabler of innovation in companies. It can be used to create new products and technologies that respond to changing market needs. At the heart of mechanical design is the ability to translate ideas into tangible products and solutions that drive technological progress and product development.

Hefmec’s mechanical design is a driving force for innovation. When we start working on a project, we focus on our customers’ needs and understanding the root causes of their problems. This approach ensures that the solutions developed are technically and economically optimal, leading to improved productivity and competitiveness.

Promoting innovation also requires agile working methods and an open culture. At Hefmec, these principles are at the heart of what we do, and they enable us to develop fast and effective solutions. While others talk about months, we talk about days. This speed and flexibility are important factors in supporting innovation and ensuring customer satisfaction.

What are the main tools and methods of mechanical design?

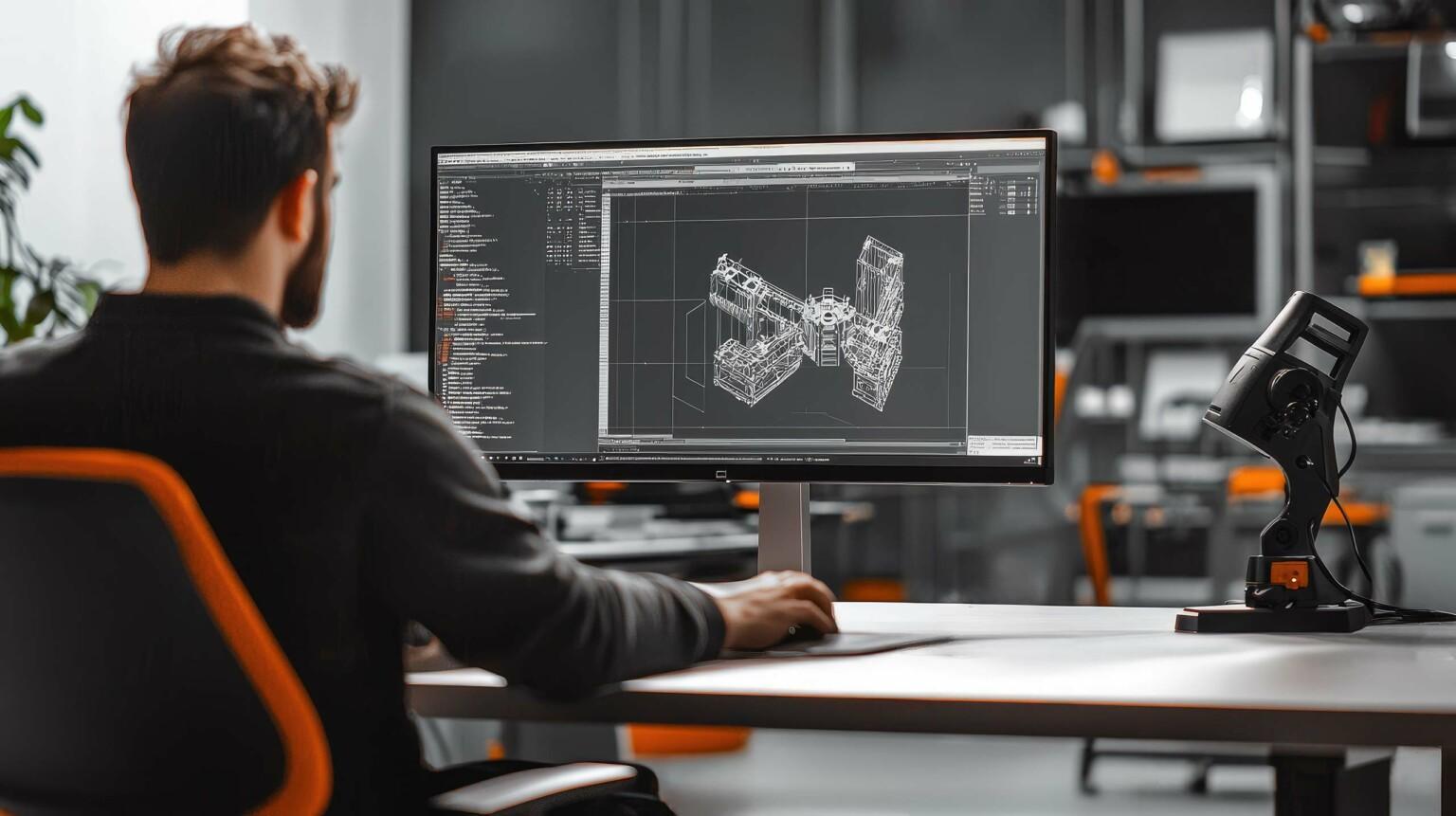

Mechanical design uses a number of tools and methods that are essential for developing innovations. Computer-aided design (CAD) software is one of the main tools that allows engineers to create accurate 3D models and simulations of designed products. These models help to visualise and test the functionality of products before they are physically prototyped.

Simulation tools are another essential part of mechanical design. They can be used to analyse the performance of products under different conditions, reducing the need for expensive and time-consuming physical tests. Simulations allow us to optimise the design of products before they are manufactured, saving time and resources.

Prototyping is also a key part of mechanical design. Physical prototypes provide the opportunity to test and improve product features before mass production. Prototypes allow potential problems to be quickly identified and solved, speeding up the product development process and improving the quality of the final product.

How can mechanical design improve competitiveness?

Effective mechanical design is key to improving a company’s competitiveness. It enables products to be brought to market quickly, which is important in today’s fast-changing market. By developing and manufacturing products efficiently, a company can meet its customers’ needs faster and stay ahead of the competition.

Cost savings can be achieved by optimising design processes and reducing material waste. Mechanical design can also help develop products that are more durable and longer lasting, improving customer satisfaction and reducing warranty costs. At Hefmec, we provide a lifetime warranty on many of our products, reflecting our commitment to quality and responsibility.

In addition, effective mechanical design enables the use of new technologies and materials, which can lead to innovative solutions and improved product performance. This in turn can lead to a stronger market position and new business opportunities.

Mechanical design services at Hefmec

Hefmec offers a wide range of mechanical design services to support your company’s innovation processes. Our expert team is ready to meet the most demanding production challenges, and we take full responsibility for all our work. We are proud to offer our customers a lifetime guarantee on many of our products, demonstrating our commitment to quality and customer satisfaction.

If you would like to know more about our mechanical design services, please visit our website at Hefmec Mechanical Design.