Careful engineering is the cornerstone of product development, determining the functionality, durability, manufacturability and practicality of a product. Engineering design defines the structural characteristics of the product, the material requirements and the relationships between components, enabling innovative ideas to be turned into tangible products. Effective mechanical design reduces production costs, improves quality and shortens time to market.

Why is mechanical design an important part of product development?

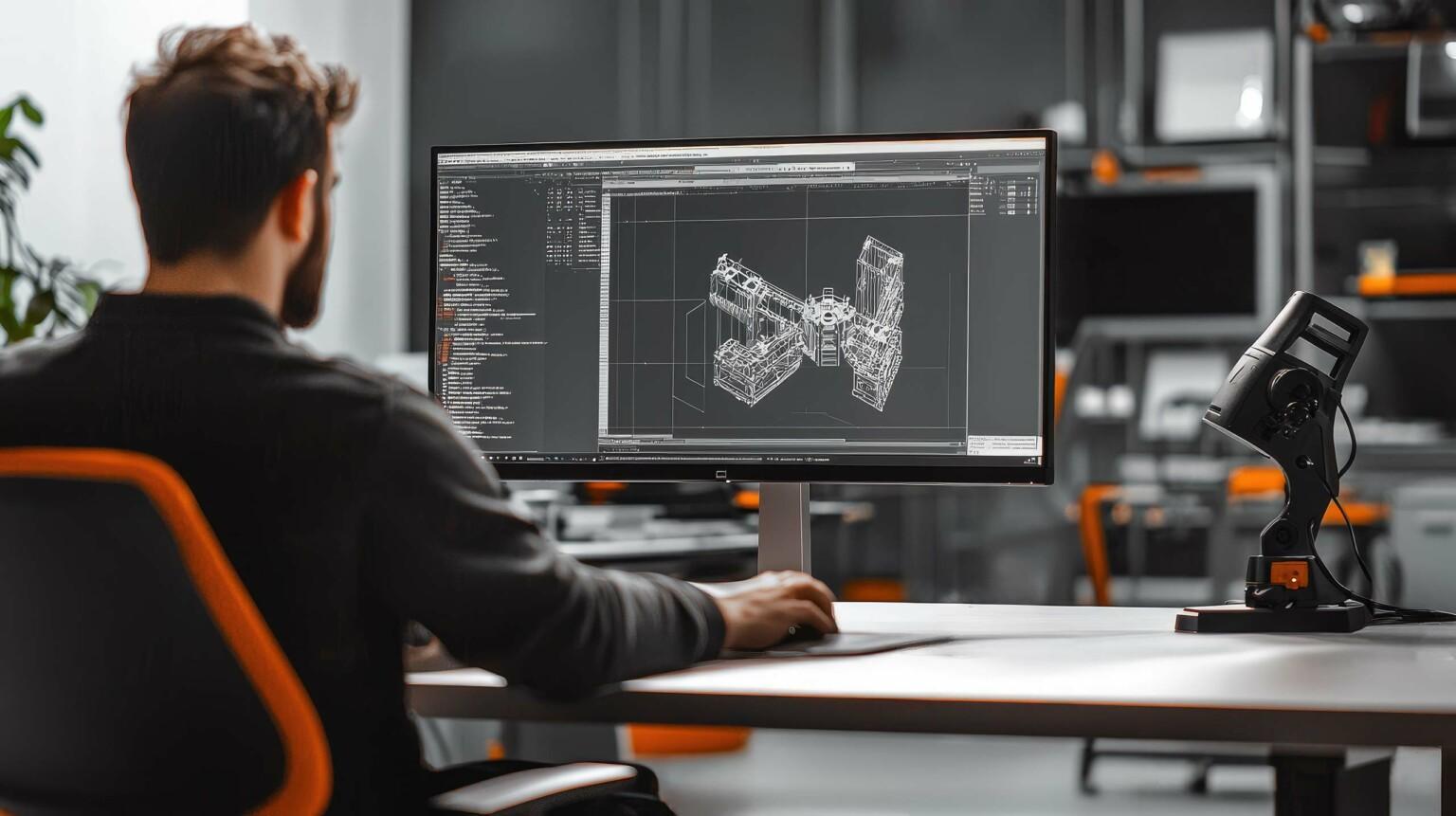

At the critical focal point of product design is mechanical design, which is the bridge between an abstract idea and a working product. It is a holistic process that takes into account the form, function and manufacturing aspects of the product. Successful mechanical design not only ensures the functionality of the product, but also its safe and reliable use throughout its life cycle.

A well-designed mechanical structure acts as the backbone of the product, withstanding the stresses of use and varying environmental conditions. At Hefmec, we see every day how the structural design of a product directly affects the competitiveness and ultimately the market position of our customers’ products. In quality product development, mechanical design is not just part of the process – it is a key factor that enables innovation to become a reality.

What exactly does mechanical design mean in product development?

Mechanical design involves the definition, development and optimisation of the physical structure, components and mechanisms of a product. It is a branch of engineering that applies engineering, materials science and structural design to achieve a functional product.

In practice, mechanical design covers several key areas:

- Structural design – determining the strength, stiffness and other mechanical properties of the product

- Material choices – selecting appropriate materials based on functionality, durability and cost

- Tolerances – defining manufacturing accuracy to ensure functionality

- Assemblies – designing for compatibility and installability of parts

- Functionality – ensuring practical functionality and ergonomics

Mechanical design differs from other areas of design by focusing specifically on the physical and mechanical properties of the product. Whereas electronic design focuses on electrical components and software design on digital solutions, mechanical design ensures that the product performs as expected in the physical world.

How does mechanical design affect product quality and cost?

Professional mechanical design is directly reflected in product quality and cost-effectiveness. A well-designed product is reliable, durable and easy to manufacture, which is reflected in the total cost of ownership throughout the product’s life cycle.

From a quality point of view, the mechanical design affects the product:

- Sustainability and reliability

- Usability and ergonomics

- Serviceability and repairability

- Aesthetics and level of finish

From a cost point of view, careful mechanical design will reduce costs significantly:

- Use of materials through optimisation

- Production time and costs

- Reduced assembly time thanks to simplified structures

- Guarantee costs due to better durability

A concrete example of cost savings is a Hefmec customer project, where the product assembly time was reduced by 40% by optimising the number of parts and fastening mechanisms. This resulted in significant annual savings in production costs, while improving product quality through reduced assembly errors.

When should a company outsource mechanical design?

Outsourcing mechanical design is a strategic decision that can bring significant benefits to a company in the right circumstances. Outsourcing makes particular sense in the following situations:

- Lack of resources – when a company’s own design team is fully staffed or lacks design expertise altogether

- Need for specific expertise – when a project requires specific expertise that cannot be found in-house

- Project urgency – when the schedule is tight and a quick response is needed

- Temporary – for one-off or infrequent planning needs

The key benefits of outsourcing are cost-efficiency, flexibility and access to a wide range of specialised expertise. Partners such as Hefmec offer deep expertise in different industries and technologies, which can bring new perspectives and solutions to product development.

The best results are typically achieved through long-term cooperation, where the external partner gets to know the client’s business and needs in depth. In this case, outsourcing mechanical design becomes a strategic competitive advantage.

How does mechanical design support innovation?

Mechanical design acts as a catalyst in the innovation process. It enables abstract ideas to be turned into working prototypes that can be used to test and refine concepts. A skilled designer can identify technical constraints and find creative solutions to them.

Key elements of mechanical design that support innovation:

- Rapid prototyping and iterative development

- Simulations and analysis before physical implementation

- Considering manufacturability already at the design stage

- Application of new materials and technologies

A good example of the power of mechanical design as an enabler of innovation is modern 3D printing technologies, where design freedom has led to the development of entirely new product structures. Such structures would be impossible to realise using traditional manufacturing methods. Skilled mechanical designers can exploit these opportunities to create products with previously unattainable features.

The role of mechanical design in future product development

Mechanical design is undergoing a major transformation driven by digitalisation, automation and sustainable development. Traditional mechanical design is being replaced by new approaches that integrate smart technologies and sustainable solutions.

Future mechanical design will emphasise:

- Digital duplicates – virtual counterparts of physical products, allowing simulation and optimisation

- Generative design – using artificial intelligence to create optimal structures

- Circular economy and sustainable development – considering the recyclability and reuse of materials

- New manufacturing methods – 3D printing and other additive technologies

At Hefmec, we see how mechanical design is becoming an increasingly integrated part of the overall product development process. The boundaries between different design disciplines are blurring as mechanical structures are seamlessly integrated with electronics and software. This requires designers to have a broader range of skills and the ability to work in multidisciplinary teams.

In future product development, mechanical design will no longer be a separate stage, but a cross-cutting aspect that will accompany the product throughout its life cycle – from concept to recycling.