What is a strength calculation?

Strength calculus is a branch of engineering that focuses on the analysis and evaluation of the durability and strength of materials and structures. The aim is to ensure that structures can safely withstand the forces and loads applied to them. This process is a key part of structural analysis, which assesses how different materials and structures react to different loads and environmental factors. Strength calculations are particularly important when designing components that are subjected to high loads or intended for use in critical applications such as aerospace or large infrastructure projects.

Why is strength calculation important?

Strength calculations are an essential part of the design process, as they help prevent structural damage and collapse. By ensuring the durability and safety of structures in advance, serious accidents can be avoided and costs saved. This is particularly important in construction and manufacturing, where errors can lead to significant financial losses or even loss of life. Strength calculations also allow us to optimise the use of materials, leading to more cost-effective and environmentally friendly solutions. The precision achieved through engineering ensures that structures meet all necessary safety and quality standards.

Where is the strength calculation used?

Strength calculations are widely used in various industries, such as construction, engineering and aerospace. It is a key part of design and product development, where the durability of structures and components must be ensured. In the aerospace industry, for example, aircraft structures must be able to withstand extreme forces and conditions, making strength calculation an essential part of their design process. In the construction industry, on the other hand, strength calculations ensure that buildings can withstand natural forces such as wind and earthquakes. In the engineering industry, it helps design machinery and equipment that can withstand daily use and stress.

How is the strength calculation done?

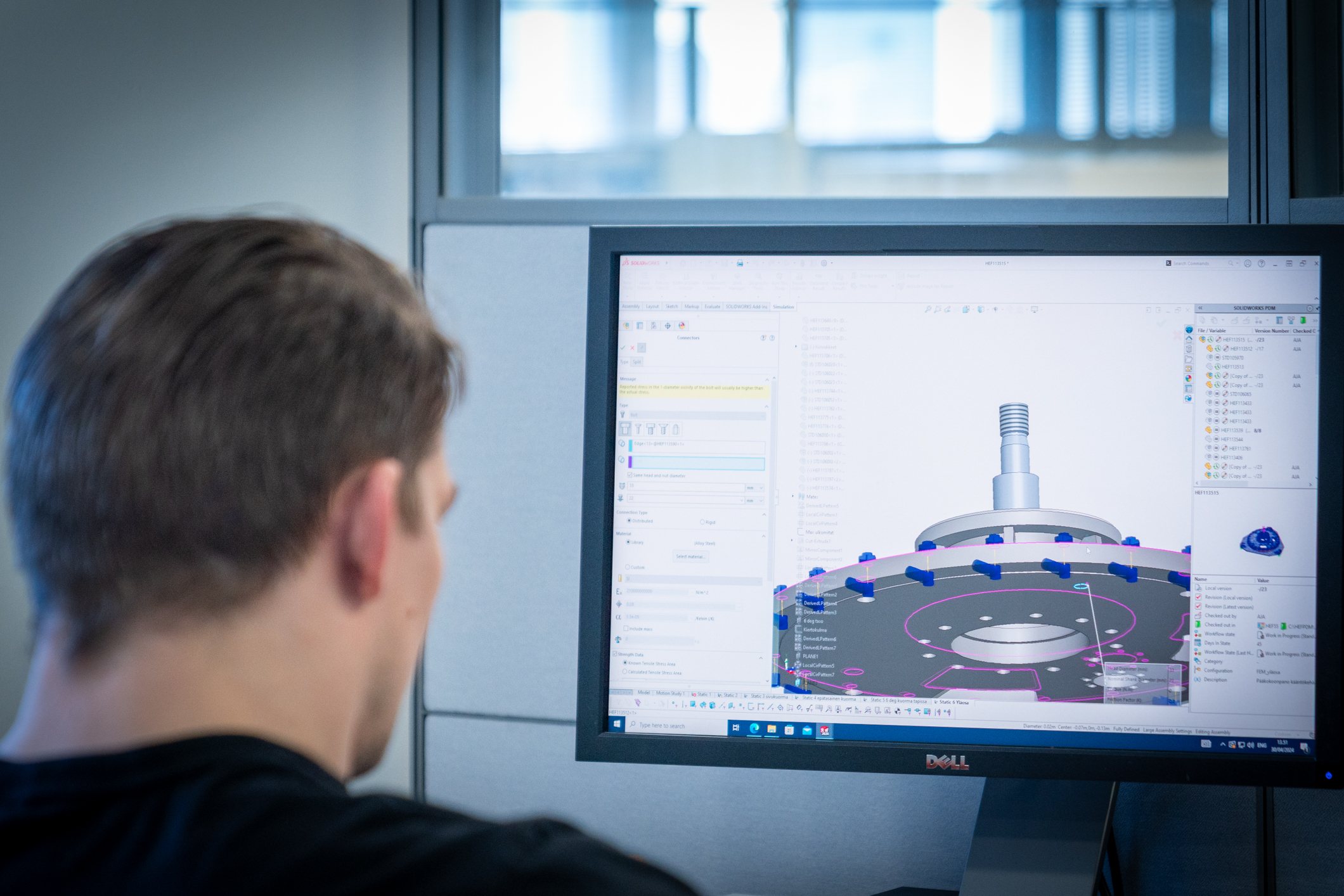

Strength calculations are usually carried out using computational methods, such as elementary methods. These methods are used to simulate and analyse structural loads and their effects. Elementary methods allow the analysis of complex structures by breaking them down into smaller parts, which makes the analysis more accurate and detailed. We use modern software that can quickly and accurately model different loading conditions and their effects on materials. This enables designers to develop safe and effective solutions.

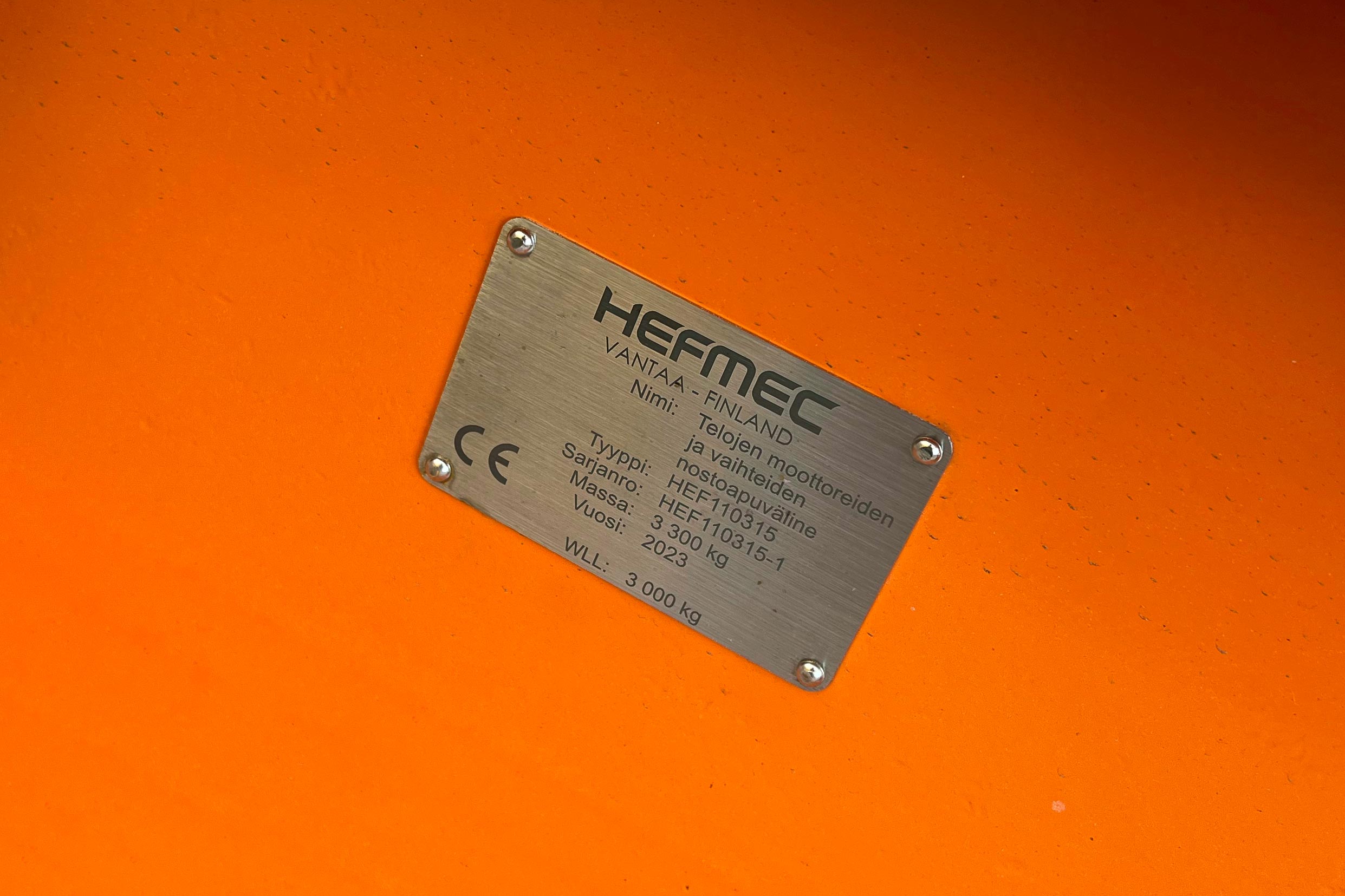

Hefmec is committed to providing its customers with high quality strength calculation services. We have extensive experience in the field and can meet the most demanding industrial production problems. We offer our customers a lifetime guarantee on many of our products, which reflects our confidence in the quality of our work. To find out more about our services, please visit our website at Hefmec Strength Calculation Services.