Heavy industrial equipment requires specialised skills and equipment when it is moved to high or inaccessible places. Effective moving relies on careful planning, the right lifting equipment and the skills of professionals. Modern lifting methods, such as industrial lifts, special cranes and customised tools, allow safe movement to the most challenging locations. The use of specialised equipment and proper project planning minimise risks and guarantee the reliability of the equipment well into the future.

What are the most efficient methods for moving heavy equipment to high spaces?

Moving heavy industrial equipment to high spaces requires special tools and expertise. The most effective methods depend on the size and weight of the equipment to be moved and the specific characteristics of the space to be moved. Choosing the optimal method is a critical part of a successful project.

Industrial cranes are the most common type of equipment used to move heavy equipment. Modern tower cranes can lift equipment weighing up to several tonnes to heights of tens of metres. In-building overhead travelling cranes allow precise positioning in industrial halls.

Industrial lifts offer an alternative when lifting needs to be carried out in confined spaces or inside a building. Special lift solutions supplied by Hefmec are designed for the safe and efficient transfer of heavy loads.

Special tools such as hydraulic jacks, chain slings and specially designed transfer devices complement the lifting methods. Hefmec’s tailor-made tool solutions allow you to work efficiently even in challenging conditions. Machine turntables, tank tipping racks and specially designed lifting equipment facilitate the positioning of equipment in high spaces.

How do you ensure safety when moving heavy equipment?

Safety is paramount when handling heavy equipment in high or inaccessible areas. Careful planning, risk assessment and skilled personnel are the basic prerequisites for a successful and safe transfer operation.

Comprehensive safety planning starts with a thorough risk assessment. Each stage of the transfer is analysed and potential hazards are identified in advance. Hefmec’s experts will draw up a detailed safety plan that takes into account all the specificities of the project.

Appropriate permits and certificates are essential. Special lifting operations often require regulatory approval, and lifting equipment must meet strict safety standards. Hefmec ensures that all necessary CE documentation and safety regulations are met.

Professional staff are a guarantee of safety. Personnel operating lifting equipment must have adequate training and experience. Hefmec teams are made up of certified professionals with in-depth knowledge of the equipment and procedures.

When should you outsource equipment maintenance in hard-to-reach areas to professionals?

It is worth outsourcing the maintenance of equipment in hard-to-reach areas to professionals, especially when the work requires specialised skills or equipment. Using experts saves time, money and improves safety in many situations.

Complex lifting and moving operations require specialised skills. Servicing equipment at height or in confined spaces requires both technical knowledge and experience in challenging working environments. Hefmec’s specialists have years of experience in difficult maintenance tasks.

Cost-effectiveness is a major advantage of outsourcing. While using in-house staff may seem cost-effective, the cost of purchasing and maintaining specialised equipment and training needs often makes it more cost-effective to use professionals. Hefmec’s service and maintenance services offer a complete solution without high fixed costs.

For example, one of our industrial customers had equipment that needed regular maintenance at a height of 15 metres. By outsourcing maintenance to Hefmec, they saved significant labour time and minimised safety risks by being able to carry out maintenance cycles efficiently with the right tools.

What are the specific requirements for moving industrial equipment into confined spaces?

Moving industrial equipment into confined spaces presents specific challenges that require careful planning and special solutions. Space constraints, access routes and equipment dimensions must be considered in detail.

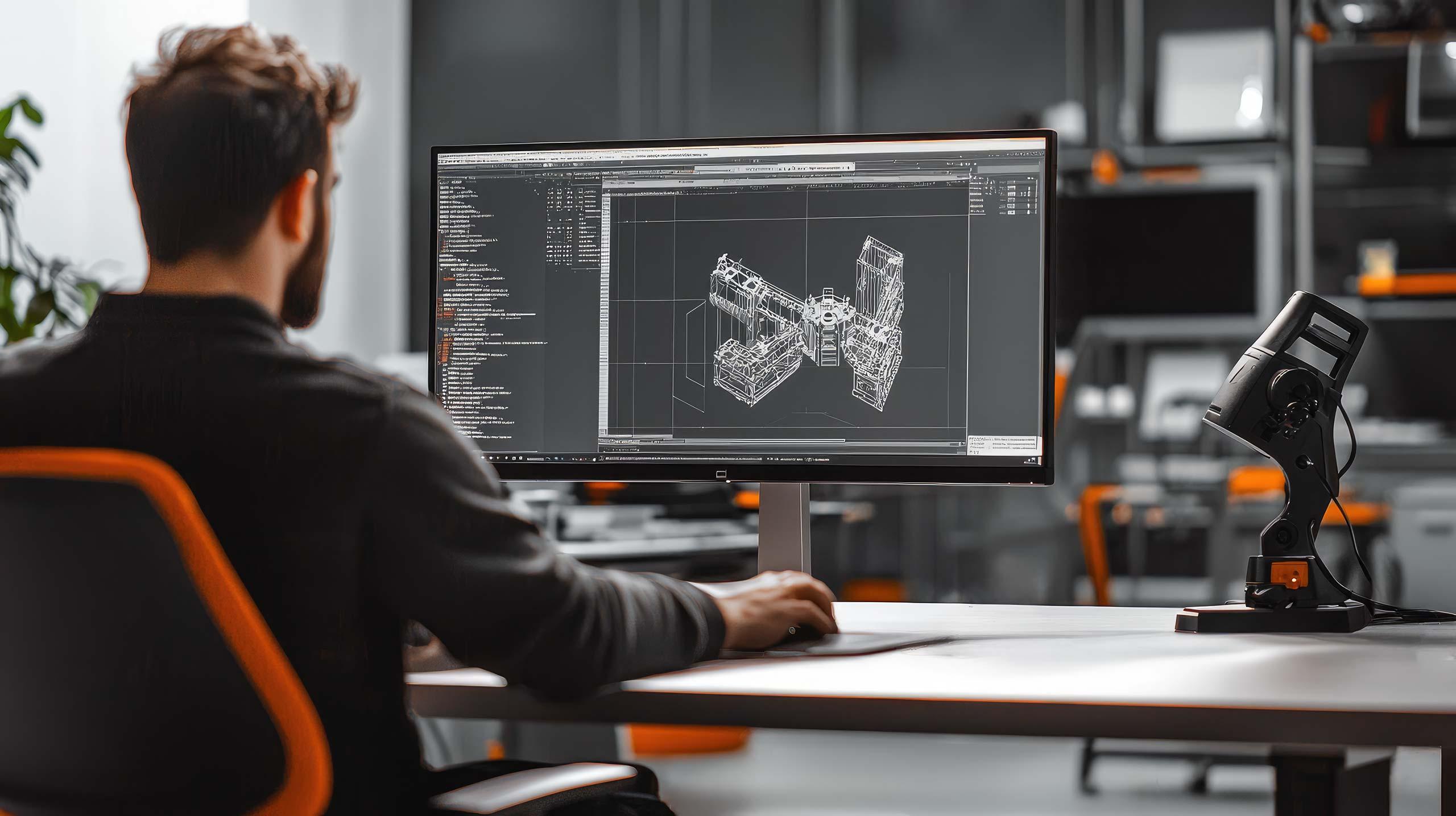

Accurate measurements and modelling are essential. Before moving, it is important to map the dimensions of the space, access routes and possible obstacles. Hefmec’s experts use 3D modelling and laser measurements to ensure that the equipment will fit into its destination.

Specialised equipment allows you to carry out even the most difficult moves. Hefmec’s modular transfer equipment, narrow trolleys and adjustable hoists are designed to operate in limited space. Hydraulic pushers and custom-built skateboards make it easy to move heavy equipment in narrow aisles and doorways.

The accuracy of the installation plan is key. If necessary, Hefmec’s experts will divide the mobile equipment into parts that can be assembled at the final location. This modular approach allows even large equipment to be placed in confined spaces.

How do Hefmec’s maintenance services support the life cycle of equipment in inaccessible spaces?

Special attention is needed to manage the life cycle of equipment that is located at a high altitude or otherwise difficult to reach. Hefmec’s maintenance services are designed to maximise equipment life and minimise unexpected downtime.

A comprehensive maintenance programme covers all stages of the equipment life cycle. Tailored maintenance plans take into account the specific characteristics of each piece of equipment and the challenges posed by its location. Regular inspections and preventive maintenance significantly extend the life of equipment.

Proactive maintenance reduces costly downtime. Hefmec experts identify and correct potential problems before they lead to equipment failure. Condition monitoring systems enable continuous monitoring of equipment status, even in hard-to-reach locations.

At our industrial customer’s paper mill, Hefmec’s predictive maintenance programme reduced unplanned downtime by 78% on high-rise conveyor systems. Maintenance and inspection activities were planned to be carried out during production shutdowns, minimising production downtime.