Challenges and solutions for industry

Every day, we face challenges in industry that require in-depth expertise and technical skills. Our mission is to provide our customers with reliable solutions that not only meet their immediate needs, but also support the long-term development of their production. We are committed to listening carefully to our customers and identifying the root causes of problems in order to provide targeted and effective solutions.

In practice, this means that we approach each project individually, using our flexible working methods and open culture. This allows for fast response times and tailor-made solutions that are both technically and economically optimal. This approach is valued by our clients as it delivers results that not only solve the problems at hand, but also improve future productivity.

Project management and accountability

In project management, we emphasise accountability and our ability to deliver projects on time and within budget. When we take on a task, we commit ourselves fully to it and ensure that all aspects of the project are carefully planned and executed. Our clients can be confident that when we get down to business, our commitment is firm and the quality of our work is excellent.

Responsibility is also reflected in the way we take the environment and safety into account in all our activities. We continuously strive to improve our processes and working practices to provide better and more sustainable solutions for our customers. This is part of our commitment to quality and customer satisfaction, which is extremely important to us.

Customer focus and tailored solutions

Customer focus is at the heart of what we do. Every project starts with a thorough mapping of the client’s needs and expectations. This enables us to provide services and solutions that meet the client’s individual challenges. It is important to us that our clients feel understood and that their problems are solved effectively.

Our tailor-made solutions are the result of years of experience and in-depth technical knowledge. We pride ourselves on providing services that not only meet but exceed our customers’ expectations. This is possible because we continually invest in learning and development to stay at the forefront of our industry.

Technical expertise and innovation

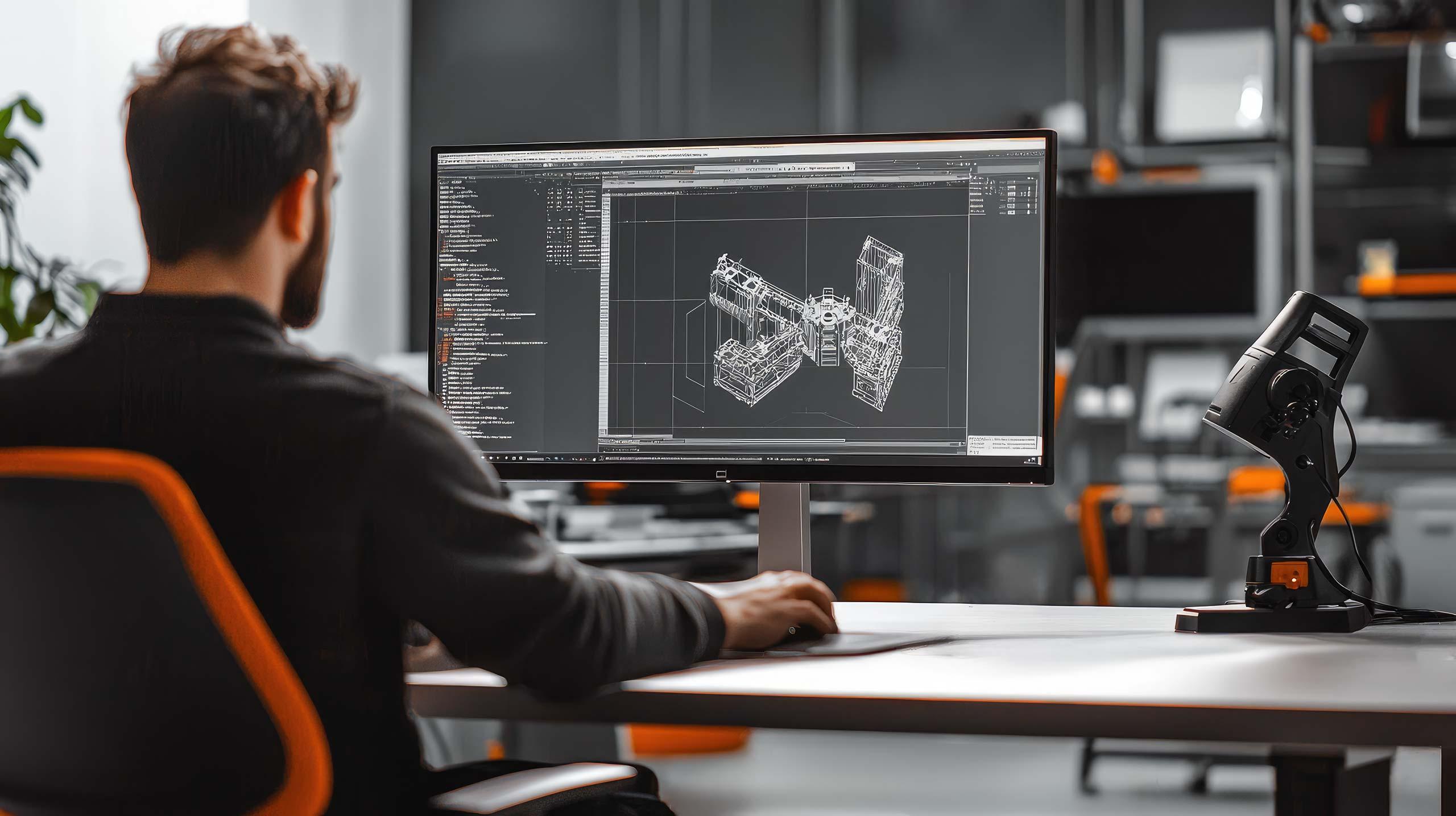

Our technical expertise is the foundation on which we build all our services. We specialise in solving complex industrial problems and are able to offer innovative perspectives that improve the efficiency of our customers’ machines and production processes. This requires constant monitoring of technology and methods and the ability to apply new innovations in practice.

Innovation is not just a word for us, it is the way we approach every challenge. We always strive to find new and better ways of doing things, and this is reflected in our results. Our customers benefit from this, because they get solutions that are not only effective, but also sustainable and forward-looking.