Role and responsibilities of the mechanical designer

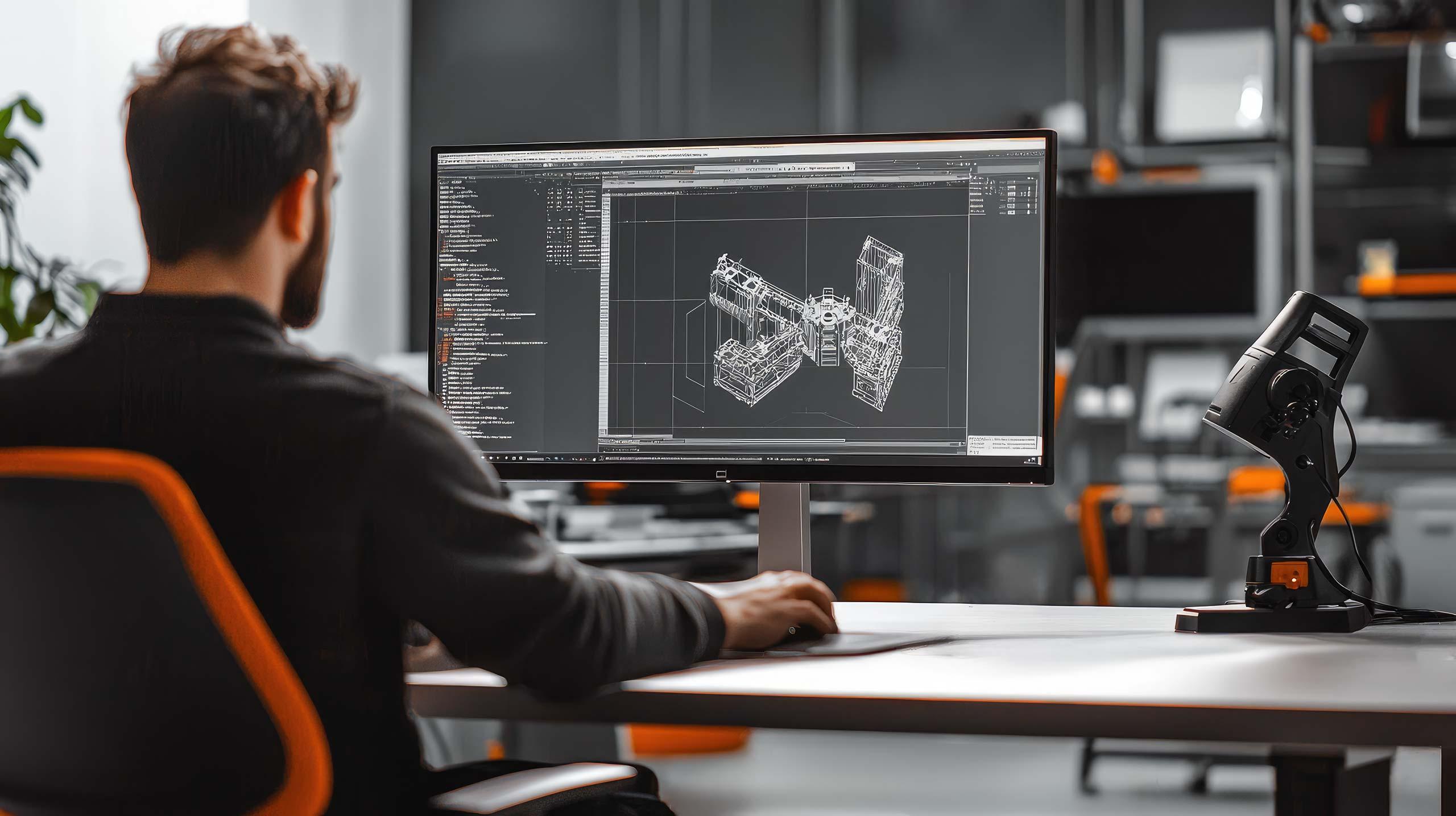

Mechanical engineers play a key role in the development of industrial innovation and production efficiency. Daily tasks include engineering design using advanced design tools such as CAD software. Using these tools, the designer creates accurate 3D models and drawings that serve as the basis for production.

Project management is another key part of a mechanical designer’s job. He or she coordinates the different phases of the project, ensuring that schedules and budgets are met. Collaboration is also an important part of the job. The mechanical engineer works closely with other engineers, such as electrical and automation engineers, to ensure that all technical solutions are compatible and work.

At Hefmec, mechanical designers take full responsibility for their projects, which means they are committed to creating sustainable and efficient solutions for our customers. This responsibility is also reflected in the fact that we can offer a lifetime guarantee on many of our products.

What skills does a mechanical designer need?

To succeed as a mechanical designer, you need a wide range of skills and competences. Knowledge of CAD software is essential as it is the basis for engineering design work. Problem-solving skills are equally important, as mechanical designers are often faced with complex technical challenges that require creative and innovative solutions.

Teamwork skills are emphasised in projects where collaboration with other engineers and clients is a daily activity. Communication skills help to ensure that all parties involved in a project are on the same page and that project objectives are met effectively. In addition, technical expertise in materials engineering, pneumatics and hydraulics is an advantage when designing reliable and efficient systems.

At Hefmec, we particularly value agile working methods and an open culture that enable us to deliver fast and efficient solutions to our customers.

Why is mechanical design important for industry?

Mechanical design is a key part of industrial development and innovation. It directly affects the quality of products and the efficiency of manufacturing processes. Well-designed mechanics can significantly improve product performance and durability, which in turn increases customer satisfaction and market competitiveness.

Efficient mechanical solutions reduce production times and material wastage, resulting in cost savings and improved company performance. Mechanical designers are responsible for ensuring that engineering solutions are not only functional, but also economically sound and sustainable in the long term.

Hefmec is committed to providing its customers with technically and economically sound solutions that will continue to improve productivity in the future. While others talk in months, we talk in days – our solutions are fast and customer-oriented.

Our mechanical design services are a key part of Hefmec’s offering. We solve mechanical and production engineering problems in various industries and are responsible for demanding production development projects. Find out more about our services.