Basics of strength of materials calculations

Structural analysis is a key area of engineering that focuses on analysing the strength and stability of structures. It involves the use of mathematical models and calculation methods to evaluate the ability of materials and structures to withstand different types of loads. Engineers use strength calculations to ensure that designed structures, such as bridges, buildings or machinery components, meet the required safety and operational requirements.

In structural design, strength calculations can be used to optimise the use of materials, reduce costs and prevent design errors that could lead to structural failure. Strength calculation not only improves product safety, but also reduces production lead times and risks. Hefmec experts specialise in providing accurate and reliable strength calculations to meet the diverse needs of industry.

The role of strength of recommendation calculations in decision-making

In decision making, strength calculations act as a critical tool to support the decisions of engineers and designers in the design and implementation of structures. Strength calculations can be used to make informed decisions about material choices, structural modifications and other critical factors that affect the success of a project.

For example, in the construction industry, strength calculations can be used to assess how different materials and structures can withstand natural forces such as wind and earthquakes. In the manufacturing industry, it helps optimise the design of machine parts to withstand the stresses of use over the long term. In the decision-making process, strength calculations reduce uncertainty and provide experts with a clear view of structural performance.

The impact of technology on strength calculations

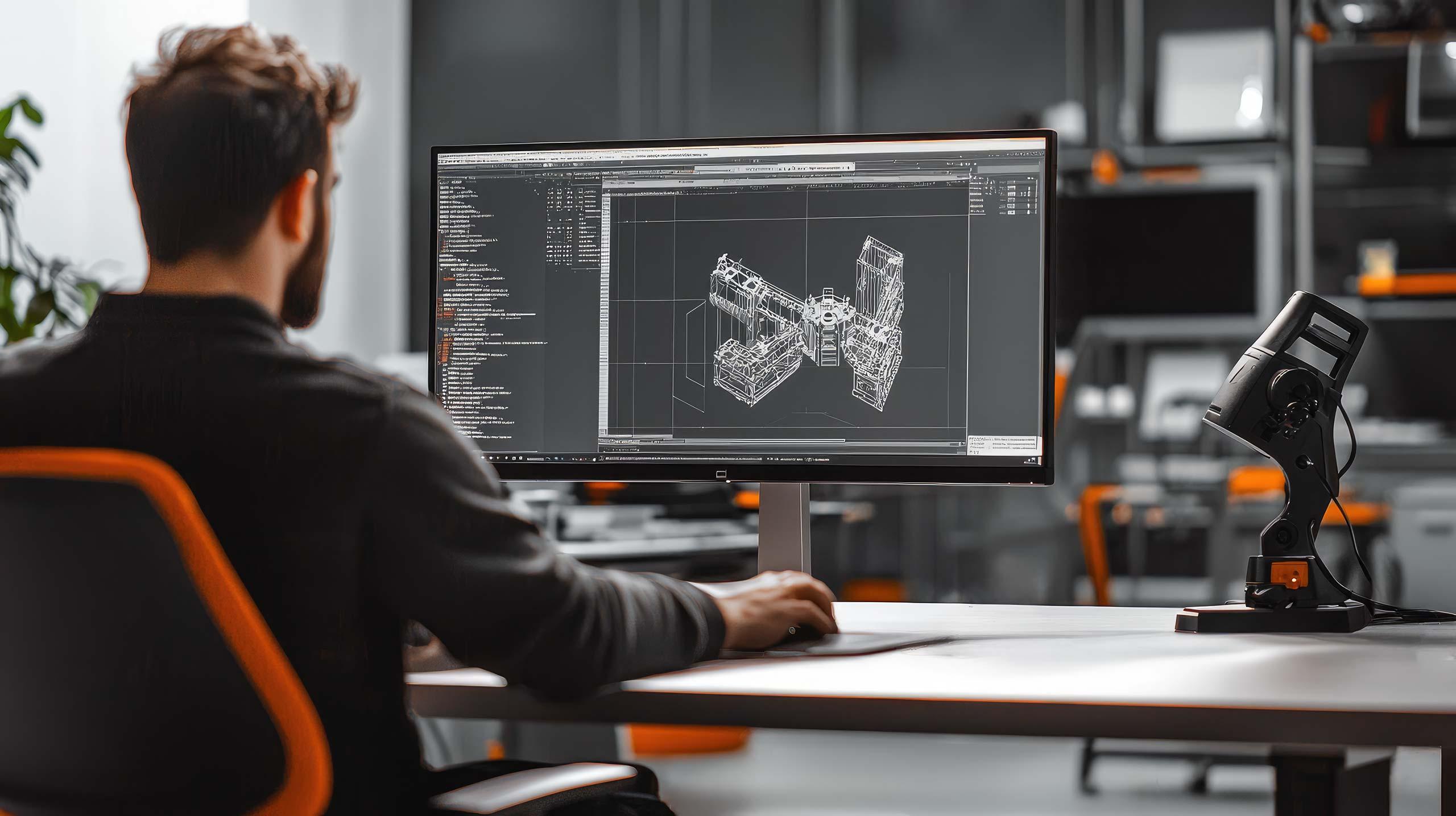

Advances in modern technology and software have revolutionised strength calculation processes, improving accuracy and efficiency. Computer-aided design (CAD) and finite element analysis (FEM) software allow accurate modelling and analysis of complex structures. These tools allow engineers to simulate various loading conditions and analyse the behaviour of structures in detail.

With technology, the calculation time has been significantly reduced, allowing for faster decision-making processes. While traditionally we talk about months, technology can provide solutions in days. Hefmec uses industry-leading technology to provide customers with reliable and fast strength calculations that support all phases of a project.

The potential of strength of field calculations

Structural calculus faces many current challenges, such as increasing complexity and resource requirements. Complex structures and extreme loading conditions require accurate and careful analysis, which can be time-consuming and require significant resources. In addition, continuous technological advances require engineers to constantly learn and adapt to new tools and methods.

Strength calculation is a key part of Hefmec’s services. We offer a wide range of strength calculation services to help our customers ensure the durability and safety of their structures. We use our extensive knowledge and advanced tools to provide our customers with accurate and reliable analyses. Find out more about our services.