Developing production and making investments may seem like straightforward decisions – add machines, increase capacity and expect production to grow in proportion. But is it really that simple?

Why don’t 10 machines always produce twice as many?

If 5 machines produce 5 products per minute, why wouldn’t 10 machines produce 10 products in the same time? The answer lies in the overall production process: material stocks, intermediate stocks, material flows and labour load can limit capacity growth. Simply adding more machines does not automatically mean more efficient production if other critical resources are not kept up.

The problem has also been that simulation software costs a lot of money and there is a shortage of simulation experts. In many cases, it has been cheaper to buy an extra machine than to do the necessary simulations. But not anymore.

A cost-effective solution for optimising production

Now we finally have a cost-effective solution for this market that allows production capacity to be accurately optimised – without the need for rigid simulation models and high costs. The simulation model can be easily built, even for an entire factory and thousands of different product variants.

At Hefmec, we have already helped many of our customers to use these simulations to assess the return on investment and optimise the number of production machines and the necessary intermediate stocks when increasing production capacity. These analyses help us to identify which investments really add value – and not just more machines waiting on the production line.

How do production simulations help decision-making?

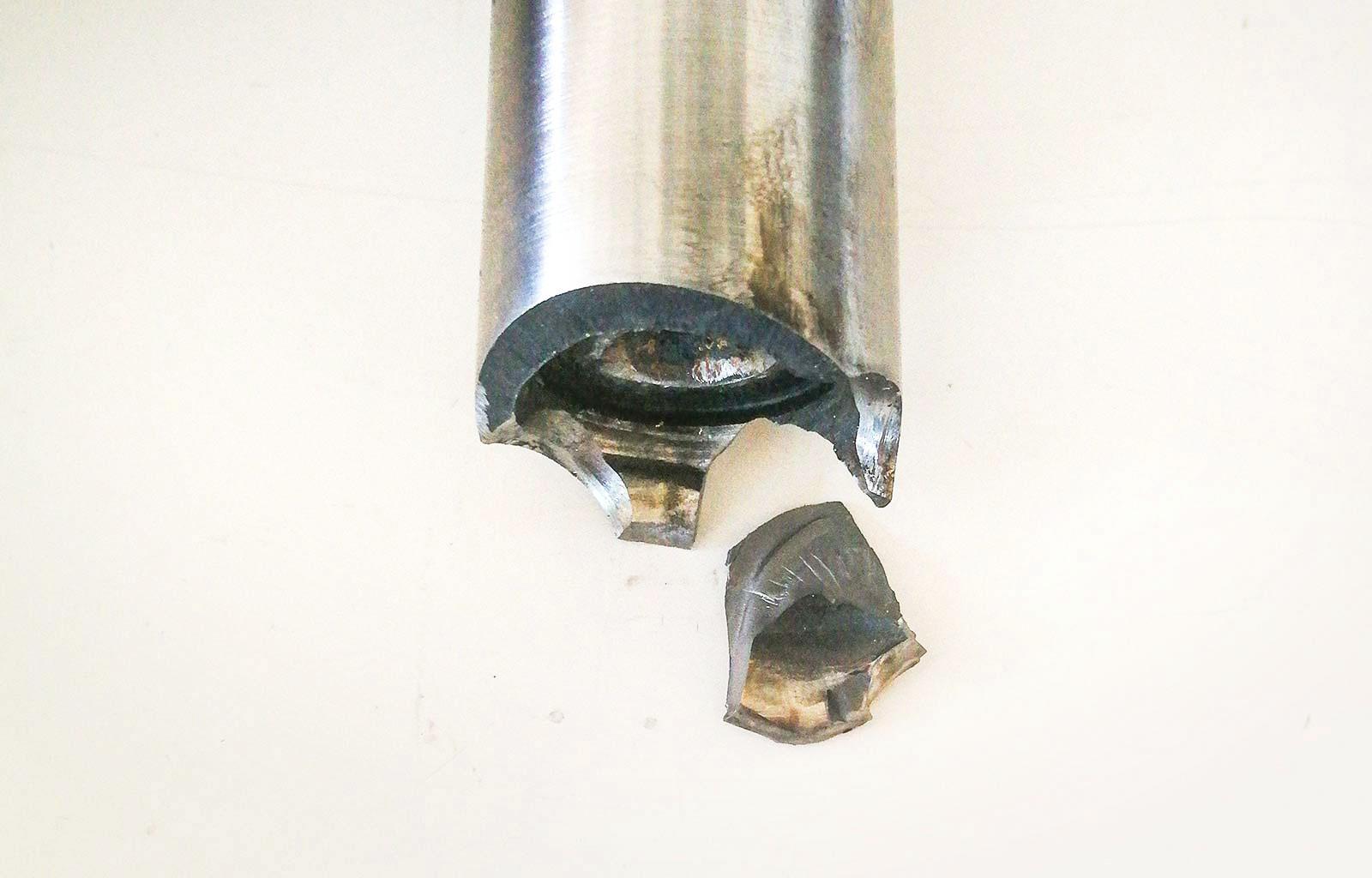

- Identifying bottlenecks – Simulations can be used to identify where production slows down and what factors are limiting capacity.

- Optimising resources – Matching machinery, labour and material flows improves efficiency and reduces waste.

- Cost management – By simulating different investment options, it is possible to predict which solutions will deliver the best return.

- Real-time validation – Our simulations are not just based on theoretical models – we have validated them with real production data. This means that our models reflect real production conditions and we ensure that they are accurate enough to predict the impact of investments.

Read more about our services and products or contact us!

Written by Sami Jortikka, Senior Project Manager