The role of the mechanical designer in problem solving

Mechanical designers are key problem solvers in complex industrial projects. His/her starting point is to identify and analyse problems in depth, which requires not only technical skills but also the ability to understand the customer’s needs and objectives. Problem solving often starts with careful data collection and root cause analysis. This step is critical, as a misunderstood problem can easily lead to the wrong solutions.

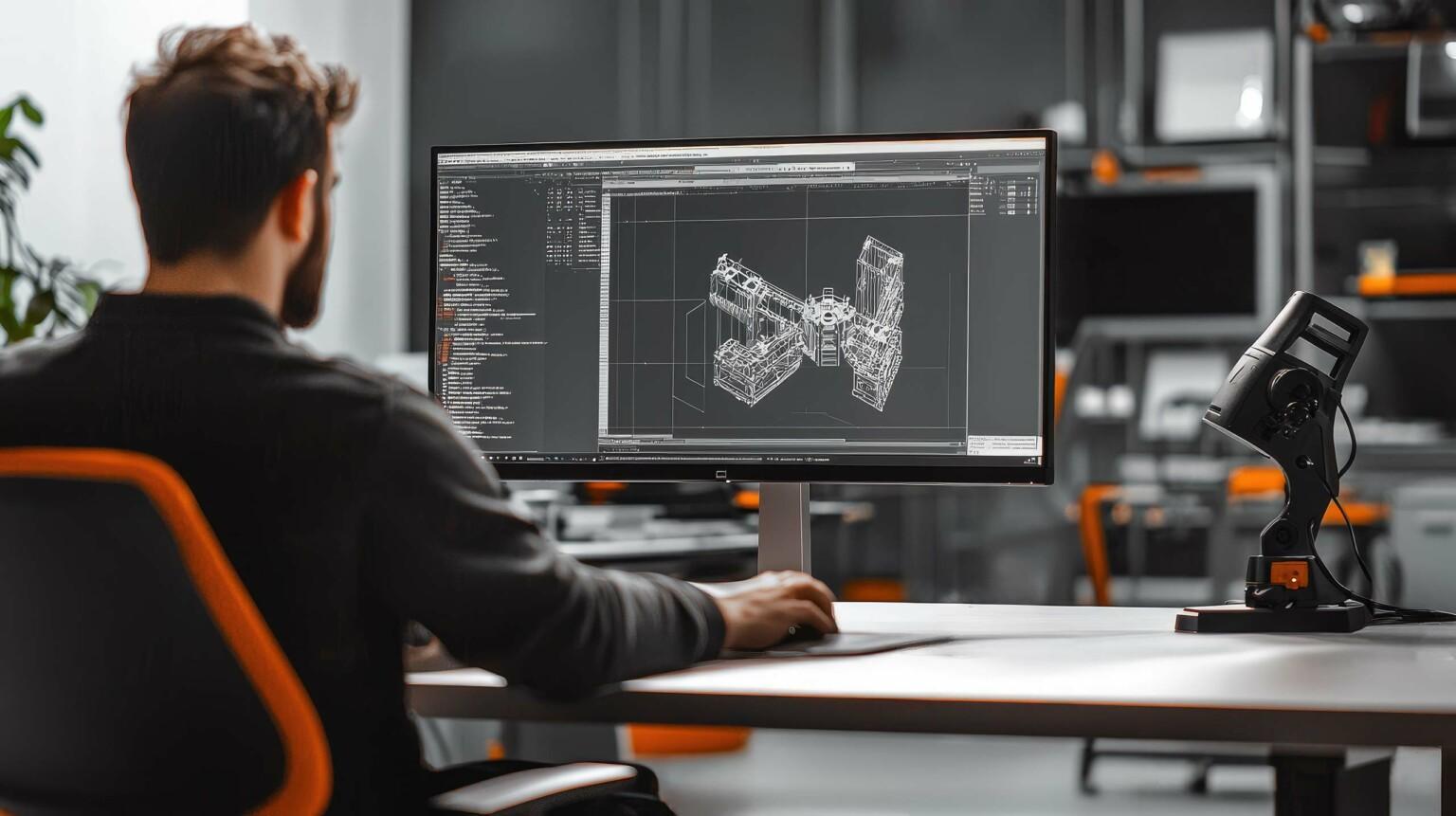

Once the core of the problem is identified, the mechanical designer uses his technical expertise to develop innovative solutions. This often involves the use of different design tools and software, such as CAD. During the design process, the mechanical designer works closely with other experts and stakeholders, ensuring that all perspectives are taken into account. This collaboration is an essential part of the process, ensuring that the solution developed is both technically and economically optimal.

How does mechanical design benefit businesses?

Mechanical design can offer significant benefits to companies seeking to improve productivity, efficiency and innovation. The engineering solutions developed by a mechanical designer not only solve current problems, but also help anticipate future challenges. This proactive approach can bring significant cost savings and improve competitiveness.

Companies that invest in high-quality mechanical design often see improvements in production efficiency and quality. For example, well-designed mechanical engineering projects can reduce downtime and increase production line flexibility. In addition, the ability of mechanical designers to innovate can open up new markets and business opportunities, which is particularly important in a global economy.

Typical tools and techniques

Mechanical design uses a wide range of tools and techniques to solve complex problems. CAD software such as SolidWorks, Inventor and CATIA are key tools that allow designers to create accurate and detailed models. These software tools also allow simulations and analyses to be carried out to help predict how a designed device or system will perform under real-world conditions.

In addition to simulations, mechanical designers use prototyping and testing methods to ensure that solutions work in practice. Prototypes provide an opportunity to test and fine-tune designs before large-scale deployment, which can reduce risk and improve the quality of the final product. In addition, expertise in materials engineering and strength calculations is often needed to select the right materials and ensure the durability of structures.

Hefmec’s mechanical design services are a key element in the success of many companies. We are committed to providing our customers with innovative and effective solutions that not only solve current problems, but also help anticipate and meet future challenges. Learn more about our services and contact us at Hefmec Mechanical Design.