The role of mechanical design in the product life cycle

Mechanical design is a critical part of the product life cycle, as it has a significant impact on the durability and performance of the product. Decisions made at the design stage determine the manufacturability, operating costs and recyclability of the product. Well-designed mechanics can extend the life of a product and improve its reliability, reducing the need for maintenance and repair.

The product life cycle starts with the design phase, where mechanical design lays the foundation for the structure and functionality of the product. During the design phase, materials and components are selected that contribute to the product’s durability and environmental impact. In the production phase, mechanical design ensures that the product is cost-effective to manufacture and meets all quality requirements.

During use, the mechanical design influences how easily and safely the product can be used. Ergonomic and intuitive design improves the user experience, which can extend the life of the product. Finally, in the recycling phase, mechanical design can facilitate the separation and reuse of materials, thus contributing to sustainable development.

The role of mechanical design in product development

Mechanical design is a key element in the product development process, as it determines the structure and functionality of the product. The design can be used to improve the user-friendliness and functionality of the product, which is important to remain competitive in the market. Well-designed mechanics can increase the value and attractiveness of a product in the eyes of consumers.

The design process can also shorten the time to market, which is important in a fast-changing market. Our agile working methods and open culture help us to deliver solutions quickly and efficiently. This allows us to talk in months while others talk in days.

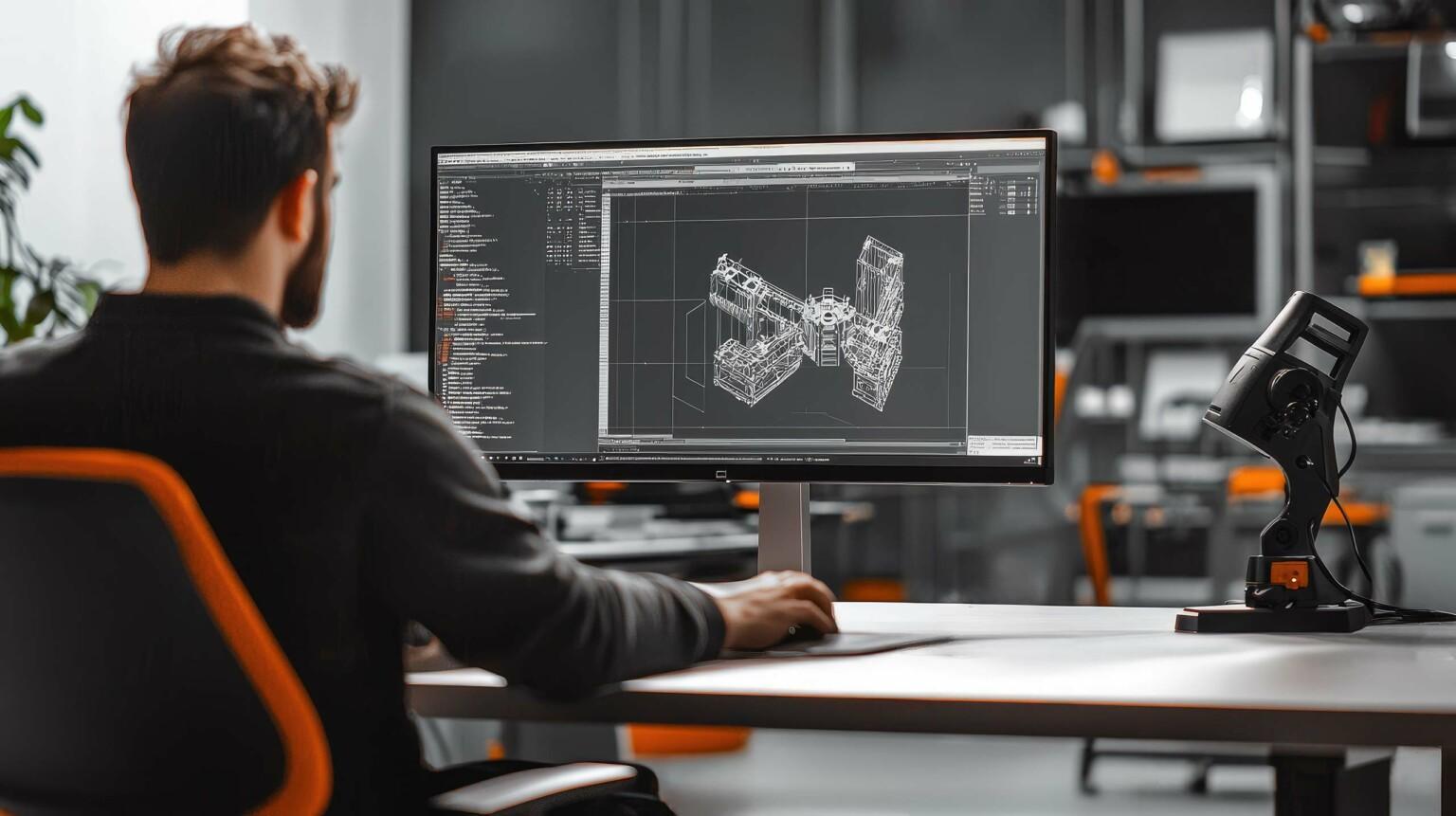

For example, when we design vehicle parts, we use modern design software such as SolidWorks and CATIA to optimise the process and ensure that the product meets all technical requirements. This careful mechanical design ensures that our products are technically and economically correct.

Optimising production processes through mechanical design

Mechanical design can significantly improve the efficiency and optimisation of production processes. The decisions made during the design process have a direct impact on production efficiency and product quality. A well-designed production process reduces material wastage and shortens manufacturing times, which in turn reduces costs.

For example, when designing the welding jig for the plate parts of a vehicle battery, we take into account the requirements of the manufacturing process to ensure the smoothest possible production. This means that mechanical design can reduce unnecessary steps and improve production line flexibility.

In industrial production, it is important that design supports the whole production chain. This ensures that products are manufactured on time and within budget, improving the profitability of the entire business. Mechanical design allows us to create solutions that meet both current and future production needs.

Hefmec offers high quality mechanical design services covering the entire product life cycle. Our aim is that the customer feels confident when we take on a project. Read more about our services.