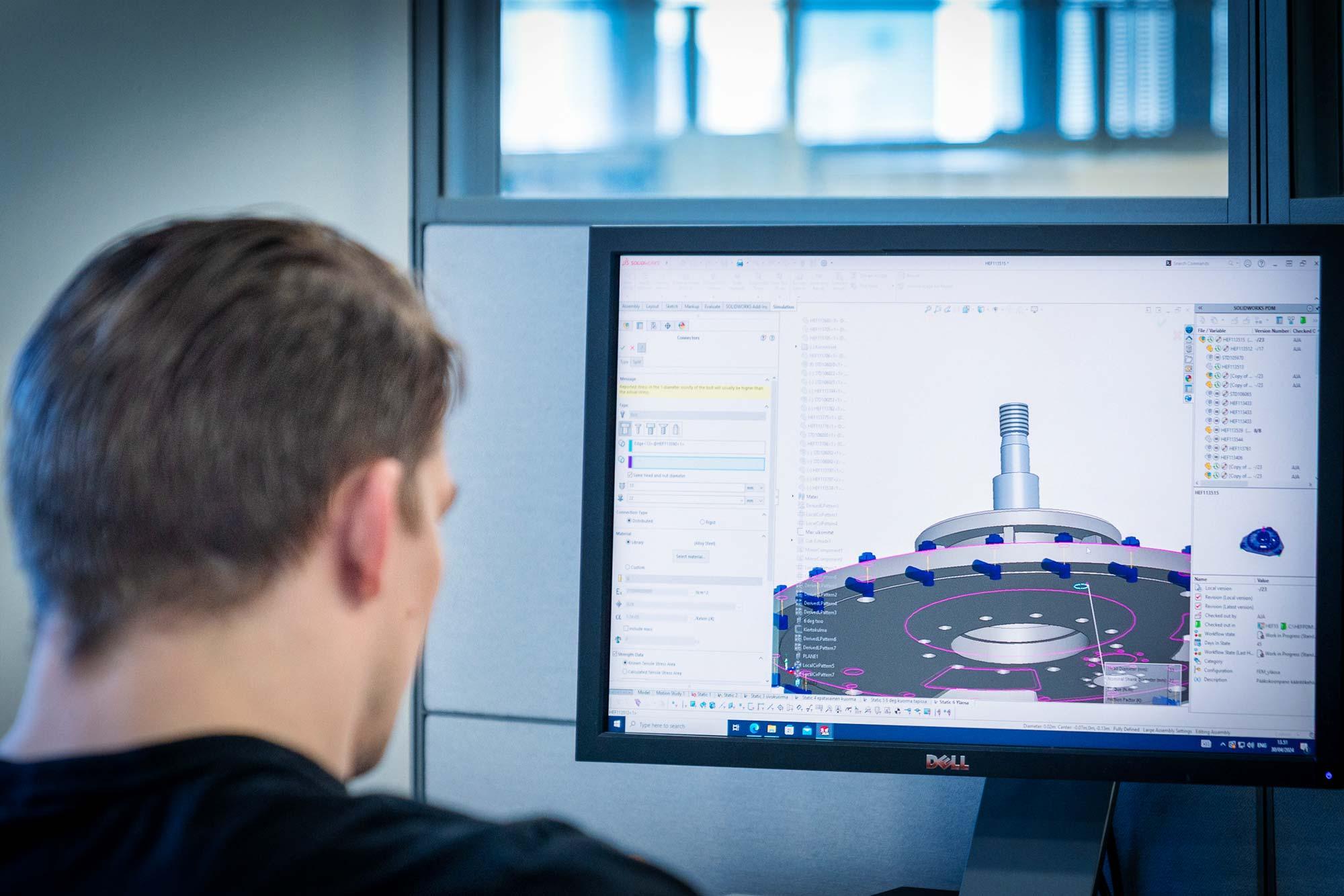

Mechanical design is Hefmec’s core competence and passion. We help our customers at every stage of the project – from conceptualisation to final assembly drawings. Thanks to our fast response and efficient working methods, projects progress smoothly and with high quality towards the desired end result.

Fast & efficient

a successful design project

Mechanical design is fast and efficient with us. We are ready to take action at short notice and provide an expert designer when you need one, even for a day at a time. We use a wide range of software such as SolidWorks, Creo, CATIA and Inventor to produce accurate 3D models and drawings quickly and reliably.

Machine drawing

Detailed working drawings

Machine drawing is a key part of an efficient production process, and we use our strong engineering expertise to help you do this. Our experienced mechanical designers produce accurate working drawings that support cost-effective manufacturing and streamline production. With our engineering expertise, we ensure that the drawings meet practical manufacturing requirements, reducing errors and speeding up production lead times.

The team

Experienced professionals

Mechanical design requires an expert team. The Hefmec design team is made up of trained engineering professionals with both practical experience and a strong theoretical background. Our engineering expertise supports efficient design and implementation. We utilise modern software such as SolidWorks, Inventor, Creo and CATIA to ensure accurate and reliable solutions.

Interested?

Contact Kimi Forsberg +358 50 563 0465 and we’ll see how we can help.

Machinery and equipment design

Machine and equipment design is a key part of Hefmec’s expertise. We develop systems and equipment for industrial needs, drawing on our engineering expertise and in-depth knowledge of engineering. Accurate machine drawings and assembly drawings ensure manufacturability and cost-effectiveness. For machine and equipment design projects, we draw on our wide-ranging expertise in areas such as strength calculation, materials engineering, pneumatics, hydraulics and machine automation.

Calculating strength

Durability and reliability of structures and components.

Materials engineering

Knowledge of material properties and their selection to maximise product performance.

Pneumatics

Design and optimisation of compressed air systems for industry.

Hydraulics

Designing and implementing liquid phase systems reliably and efficiently.

Machine automation

Designing automated machines and systems that improve production efficiency and repeatability.

Feedback

What do our customers say about us?

At a high level. The device we ordered went in the first can and works well.

The schedules were kept. The project lead time was very short and smooth.

On behalf of Hefmec, they were active in our direction. The presentations were of high quality and made it easy to show others the progress of the project.

The finish was on point! The welds were of high quality, the sharp corners were rounded. The machine as a whole was smart looking.

Lots of good stuff. Only a few times did the hourly estimates go over. Flexibility shown. Quality of service is first class.

The design process went smoothly and the solutions were exactly what we needed. Precise and efficient work.

Examples of projects

- Design of handheld robot geogrippers for vehicle components

- Preparation of the documentation required for the CE marking of a lifting accessory for propulsion equipment

- Ball valve ball lifting and turning device

- Design of special tools for vehicle parts assembly cell

- Welding jig design for vehicle battery plate components

- Design of a format trolley suitable for cleanrooms

- Design of a valve test pressure device

- Product development of fibre optic machinery

- Frequency converter product development

- Design of hydrometallurgical equipment

- Design of drawbar motor and gearbox lifting accessories

- Product development of electric motors

- Design of wind turbine service bay supports

- Design of steel structures to support production equipment

- Design of valve supports for the marine industry

- Mechanical design of a mobile service bridge

- Design of a prototype of a formatted trolley

- UV cabinet design and delivery