Services

There have always been problems in the world and those who are fascinated by them

We want the customer to feel confident when Hefmec takes on a project – and when we do, we take responsibility. That’s why our customers trust us. Our NPS score of +91 (2024), which measures our customers’ willingness to recommend us and customer satisfaction, is proof of this.

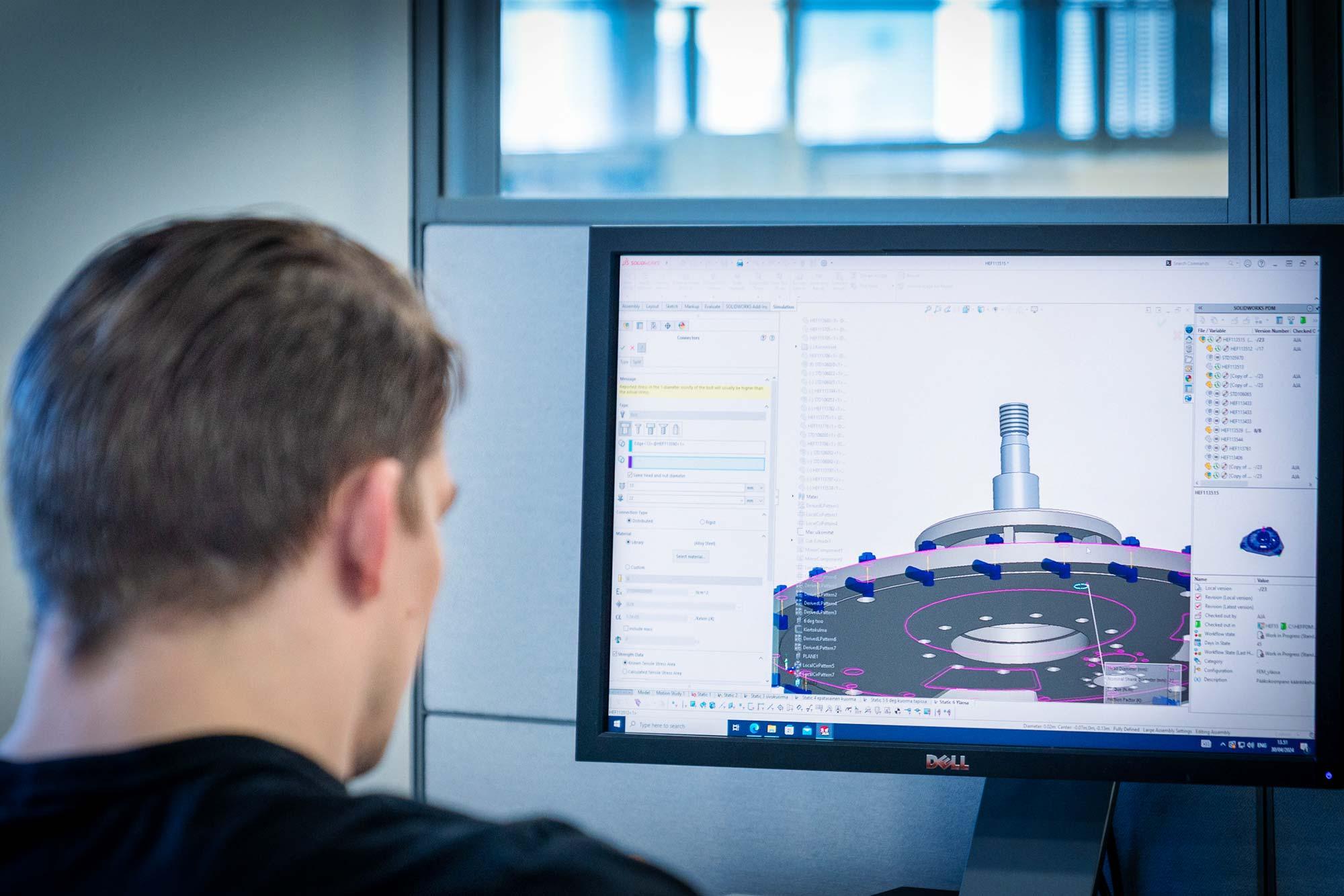

Mechanical design

Agile design assistance

Production technology, production development and product development are our strengths. Machine and equipment design and production development are part of our daily work. The tools most often used by mechanical designers are SolidWorks, CATIA, Creo, NX and Inventor.

Our modern design process motivates you to take responsibility – here

efficiency is created. The ability to take responsibility and make decisions leads to fast project turnaround times. We operate according to the Lean philosophy and are ISO 9001 certified.

Find out more about our mechanical design services and sample projects.

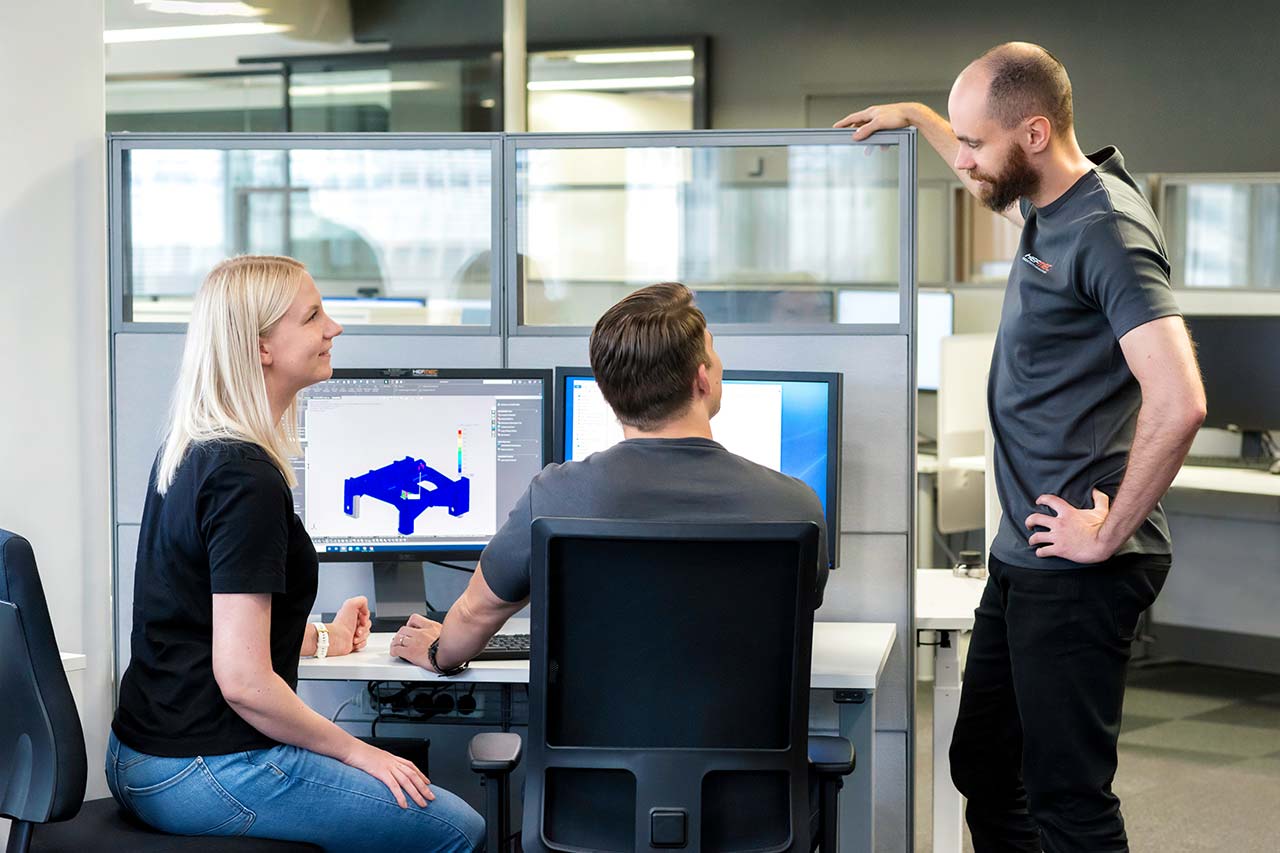

Calculating strength

Strength and reliability

Strength calculations are a key part of our expert service, where we examine the durability and reliability of structures and components. Our strength calculators use a wide range of tools, including SolidWorks Simulation and ANSYS, and FEM analyses to ensure the technical performance and safety of your designs. Whether it’s static analysis, fatigue resistance or heat transfer, we provide accurate and reliable results quickly.

We adhere to high quality standards and ensure that every project meets the required standards, while respecting the client’s expectations.

Find out more about our strength calculation services and sample projects.

PROJECTS

Technical person per week

Our experts will support your organisation from documentation to deployment. We often assemble a team including project engineers, validation professionals and designers, supported by Hefmec’s technical organisation.

We are interested in making sure that we get what you order. We’ve worked hard to find the best people in the industry, with excellent interpersonal skills and an upbeat attitude. Our customers have been particularly pleased with our good service attitude.

Our project managers are used to managing investment projects and equipment procurement projects involving many different players. We organise production transfer projects, equipment procurement projects or take care of production ramp-ups.

Our other roles include Project Engineer, Production Development Engineer, Validation Engineer, C&Q Support, Equipment Lead, Hauling Supervisor and Project Manager.

Find out more about our project and expert services and sample projects.

A day

we are talking about days, not weeks.

650€ + VAT

The day-rate project is ideal for 1-5 day assignments. Often day-rate projects are pre- and conceptual design for larger projects, small stand-alone projects such as strength testing or CE documentation.

This pricing model has become increasingly popular because it provides flexibility and makes costs easily predictable. The next steps of a daily priced project are precise and efficient, ensuring the effective achievement of the client’s objectives.

Examples of projects

- Production concepts for the Ark Platform

- Reducing assembly times in large-scale production, concepts

- Construction energy inputs, concepts

- Chocolate moulding line tooling options, concepts

- Processing of plastic boxes with cartoning machine, concepts

- Design of a format trolley suitable for cleanrooms

- Preparation of the documentation required for the CE marking of a lifting accessory for propulsion equipment

- Design of a valve test pressure device

- Product development of electric motors

- Product development of photocell support machines

- Strength calculation of wind turbine maintenance room brackets (FEM)

- Shock calculation of valve supports (FEM)

- Strength calculation of a mobile access system (FEM)

- Strength calculation of steel structures supporting production equipment (FEM)

- Preparation of validation documentation

- Design of FAT and SAT tests

- Preparation of the documentation required for the CE marking of a lifting accessory for propulsion equipment

- Production spare parts inventory and spare parts list creation

- Establishment of a shark plan and shark monitoring

Interested?

Contact Kimi Forsberg +358 50 563 0465 and we’ll see how we can help.

People

Our mechanical and production engineering experts are at your disposal wherever you need them.

Minna Savolainen

Senior Project Manager

Jeremiah Porthene

Junior Mechanical Engineer

Jesse Laakso

mechanical engineer

Jyri Lehto

mechanical engineer

Simon Hindersson

mechanical engineer

Mattias Huovinen

mechanical engineer

Andreas Rosas

Senior Mechanical Engineer

Siivertti Valanta

mechanical engineer

Said

What do our customers say about our interpersonal skills and attitude?

During the project, the flow of information was very smooth and this made the design a success.

Communication was a success. We also called back after the project and that is something that is rarely done by others. A positive experience.

The service is fast and the designer sent unsolicited information as the project progressed, which has been a really positive surprise.

Note that Hefmec has invested in good interaction. Communication is clear, people are willing to help.

Easy interaction. There was a quick response and always a review of the materials before the meeting.

The attitude to work was good. Deadlines were met and the experience was pleasant.

The project contacts had a good ability to react to changing plans and busy schedules.

The operation was straightforward. Hefmec has an advantage in certain areas.

Projects have always moved forward quickly, which is really good. Hefmec has always thought about things from the customer's point of view and what makes sense for the customer.

The Hefmec team seems to be more interested in success than the line organisation

You provide a good service! You meet deadlines, are proactive and don't leave things hanging.

The attitude is right.

Our expertise

- Mechanical design

- Mechanical engineering

- Equipment design

- Structural steel design

- Piping and process design

- Thin sheet design

- Layout design

- Concept design

- Lifting and forklift design

- 3D design

- Technical problem solving

- Technical calculation

- Technical design

- Calculating strength

- Checking strength calculations

- FEM

- Dynamic analyses

- Fatigue and stability analyses

- structural steel design calculation (Eurocode 3, AISC)

- Earthquake analyses

- Vibration analyses

- Optimisation of structures and topology

- Steel structures

- Aluminium structures

- Structures complying with the YVL regulations

- Machine structures

- CE marking

- CE marking

- CE documentation

- Preparation of manufacturing documents

- Instructions for use and maintenance

- Manufacturing and assembly instructions

- Specifications

- User requirements (URS)

- Risk analyses (EHS, GMP)

- Feasibility study

- DFMA

- Technology, safety and cost studies

- Feasibility studies

- Producing sales material

- Material reviews (Motiva)

- Labour market research

- Phase I study

- Observation survey

- Installation control

- Deployment support

- Annual inspection of the special lifting accessory

- Lean consultation

- Development of production

- Pre-production screening

- Project management

- Project management

- Project Management Service

- Project Engineer

- Production Engineer

- Bone Calculator

- Mechanical Engineer

- Development Engineer