What does a mechanical designer do?

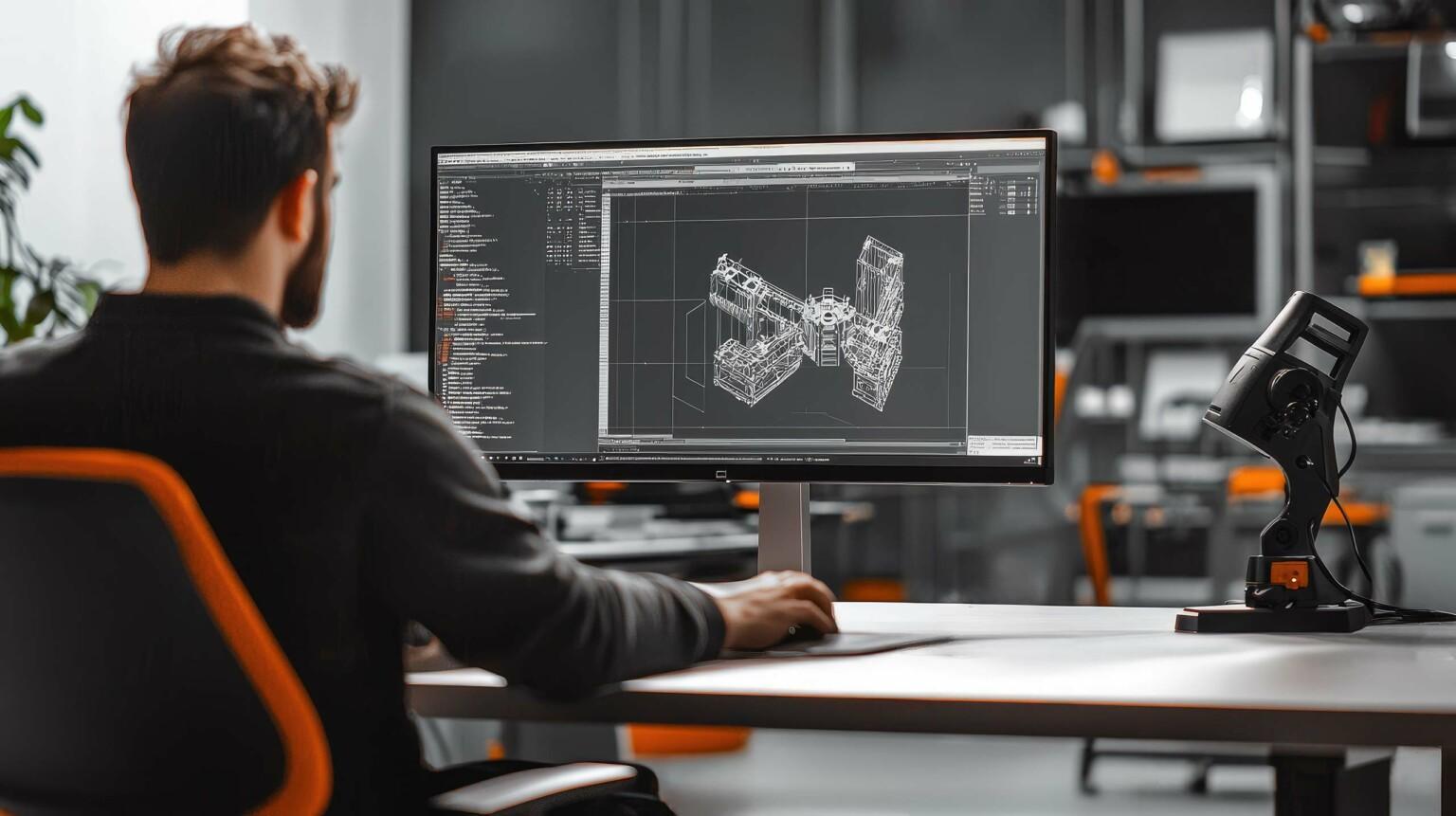

The role of the mechanical designer is central to the company, with expertise covering a wide range of design processes and technical know-how. The mechanical engineer is responsible for the design and development of machinery and production engineering, which requires a deep understanding of material properties, mechanics, pneumatics and hydraulics. The design process starts with listening to the customer’s needs and problems in order to identify the root causes of the problem and develop an optimal solution.

Mechanical designers play a key role in the early stages of a project, defining the requirements and objectives of the project. They work closely with other engineers and production teams to develop technical solutions that improve production efficiency and reduce costs. Hefmec’s mechanical design services enable clients to undertake projects large and small, such as the design of robotic geogrippers or the development of industrial lifting equipment. This ensures that our customers can rely on projects progressing smoothly and efficiently.

How can a mechanical designer improve product quality?

The professionalism of the mechanical designer has a direct impact on the quality of the product. Quality engineering design ensures that products are durable, functional and safe. The mechanical designer uses his extensive knowledge of materials engineering and mechanics to maximise product performance and durability. For example, choosing the right materials and designing efficient joints can reduce the susceptibility to failure and extend the life of a product.

Hefmec’s customers have found that the equipment and systems designed for them perform excellently and meet high quality standards. Having a mechanical engineer involved from the start of the process ensures that the design solutions are tailored to the customer’s needs. This results in significant improvements in product quality, benefiting both the customer and the company in the long term.

The impact of the mechanical designer on cost-effectiveness

A mechanical designer can make a significant contribution to the cost-efficiency of a company by optimising design processes and reducing material waste. Optimising the design process means that production processes are designed to be efficient from the outset, reducing the need for errors and rework. This saves time and money.

Material and energy efficiency are also key areas where a mechanical designer can bring significant savings. For example, a correctly sized hydraulic system can reduce energy consumption and lower costs. Hefmec’s agile working methods and efficient design solutions ensure that our customers receive technically and economically right-sized solutions quickly and reliably.

Driving innovation through mechanical design

Mechanical designers are often key to developing innovations and creating new products. Innovative design solutions can open up new opportunities and markets, contributing to a company’s growth and competitiveness. Mechanical designers bring new ideas and perspectives that can lead to major technological breakthroughs.

Hefmec’s mechanical design services are renowned for their innovation and ability to develop solutions that improve productivity. Projects such as the development of fibre optic machines and variable speed drives are examples of projects where innovative design has played a key role. By integrating new technologies and approaches, mechanical designers can contribute to the company’s ability to innovate and ensure that our customers receive competitive products that meet future needs.

Hefmec offers comprehensive mechanical design services that help companies solve challenging technical problems and achieve high quality standards. Our expert team works quickly and responsibly, ensuring that our customers feel confident at every stage of their projects. Find out more about our services at Hefmec Mechanical Design Services.