Outsourcing technical design to experts in the field offers significant benefits to companies. Specialised mechanical design brings specific expertise to projects that may not necessarily be found in-house. Outsourcing enables cost savings, optimal use of resources and improved product development efficiency. The right partner brings a wide range of expertise and modern tools to help companies respond more quickly to market challenges.

Why outsource mechanical design to experts?

Outsourcing mechanical design gives companies access to specialised expertise without the need to hire their own design team. Design professionals bring with them a depth of expertise and experience in a wide range of projects, which helps avoid common design mistakes.

Outsourcing also allows for flexible use of resources. The company can use design services exactly when they are needed, optimising the use of resources and improving cost-effectiveness. This is particularly valuable when project workloads fluctuate.

Cooperation with mechanical design professionals also improves competitiveness. Professional design speeds up the product development process and improves the quality of final products. This allows the company to focus on its core competencies while the design work is in reliable hands.

What are the economic benefits of outsourcing mechanical design?

Outsourcing offers significant cost savings as the company does not have to invest in hiring full-time designers. This turns fixed staff costs into flexible costs that scale to the needs of the project.

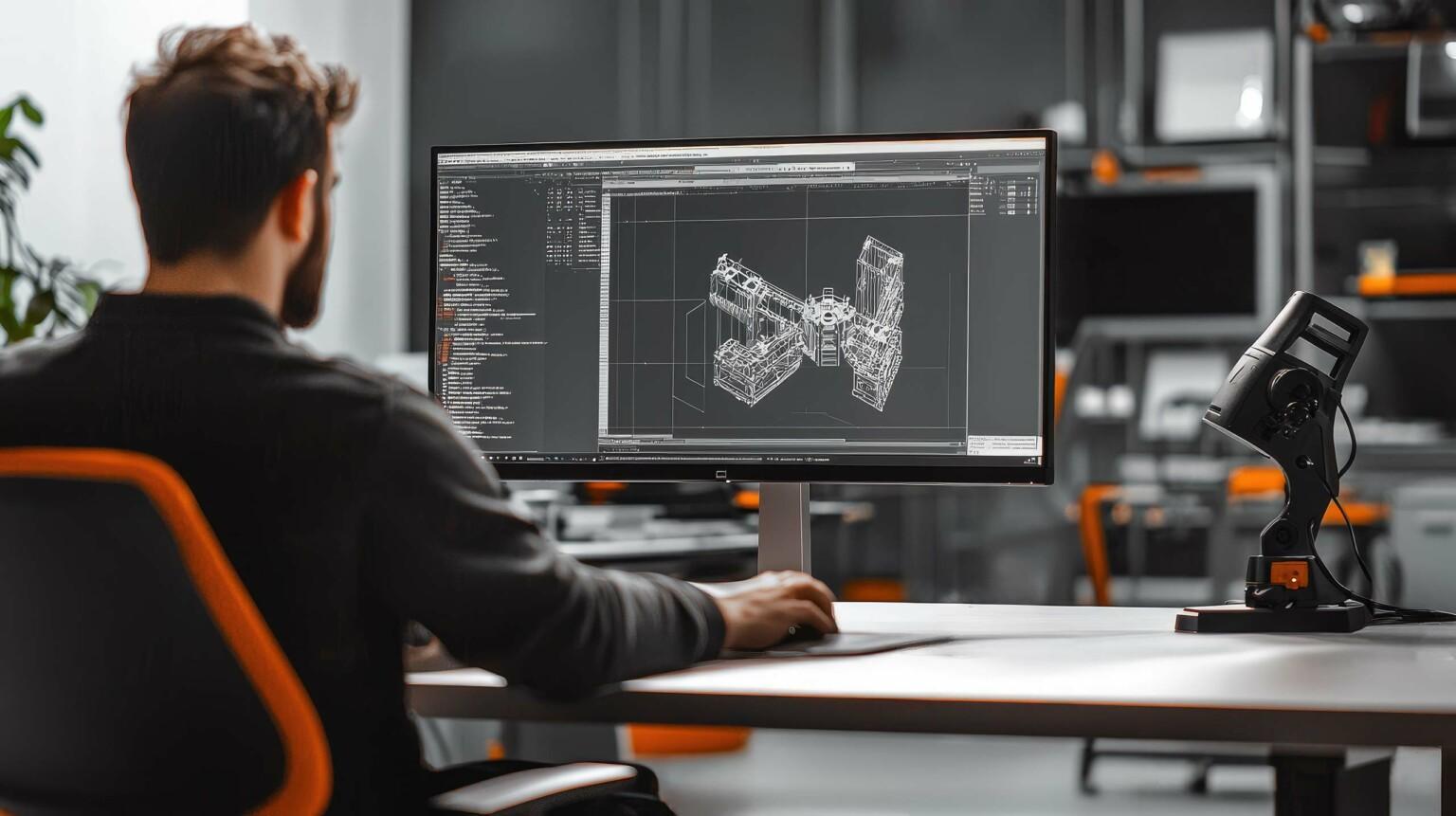

Significant savings are also made when a company does not have to invest in expensive design software and licences. Modern CAD software such as SolidWorks, CATIA and Inventor require constant updates and training. When outsourcing, these costs are included in the price of the service.

In addition, outsourcing reduces the need to invest in specialised hardware and simulation tools. This frees up capital for core business activities and improves return on investment. Design partners also bring best practices that optimise material use and manufacturing costs.

How does outsourced mechanical design affect product development time?

Professionally executed outsourced design significantly speeds up the product development process. Experienced designers identify potential challenges early and avoid typical pitfalls, reducing the need for iterations and speeding time to market.

Outsourcing also allows for parallel working, as the design of different components can be promoted in parallel. This reduces the overall time compared to sequential work, where one phase has to be completed before the next can be started.

The ability to respond quickly to peaks in demand is particularly valuable. When product development schedules tighten, an outsourced partner can provide additional resources quickly, allowing you to meet even the tightest schedule targets without compromising on quality. This flexibility is particularly important in a market where rapid response is a competitive advantage.

What skills do professional mechanical designers bring to projects?

Experienced mechanical designers bring in-depth knowledge of manufacturing processes to projects. They understand the limitations and potential of different manufacturing techniques, enabling the design to be optimised to suit the chosen manufacturing process.

Materials knowledge is another important area of expertise. Professionals know how to choose the right materials, taking into account the application, cost, availability and life cycle. This knowledge leads to more sustainable and functional products.

Simulation skills allow you to test the functioning of products virtually before prototyping. Strength calculations, flow simulations and thermal analyses help to identify problem areas in advance, saving time and costs.

In addition, professional designers are familiar with industry standards and regulations. This ensures that the products designed meet all requirements and legal obligations, which is particularly important in regulated industries such as healthcare or energy.

Main points of outsourcing mechanical design

The main benefits of outsourcing are flexibility, specialisation and cost-effectiveness. To achieve these benefits, it is essential to choose a partner who truly understands your business needs and the specificities of your industry.

When choosing a partner, you should pay attention to documented references and ask for concrete examples of previous projects. Openly discuss expectations, timelines and communication processes at the beginning of the collaboration to establish clear ground rules.

A smooth start to cooperation requires careful project definition. The clearer the initial data and requirements you can provide, the more efficiently the planning process will start. Modern mechanical design requires both technical expertise and creative problem-solving skills – and that’s what we can bring to your projects, whether it’s a single component or an entire production line.