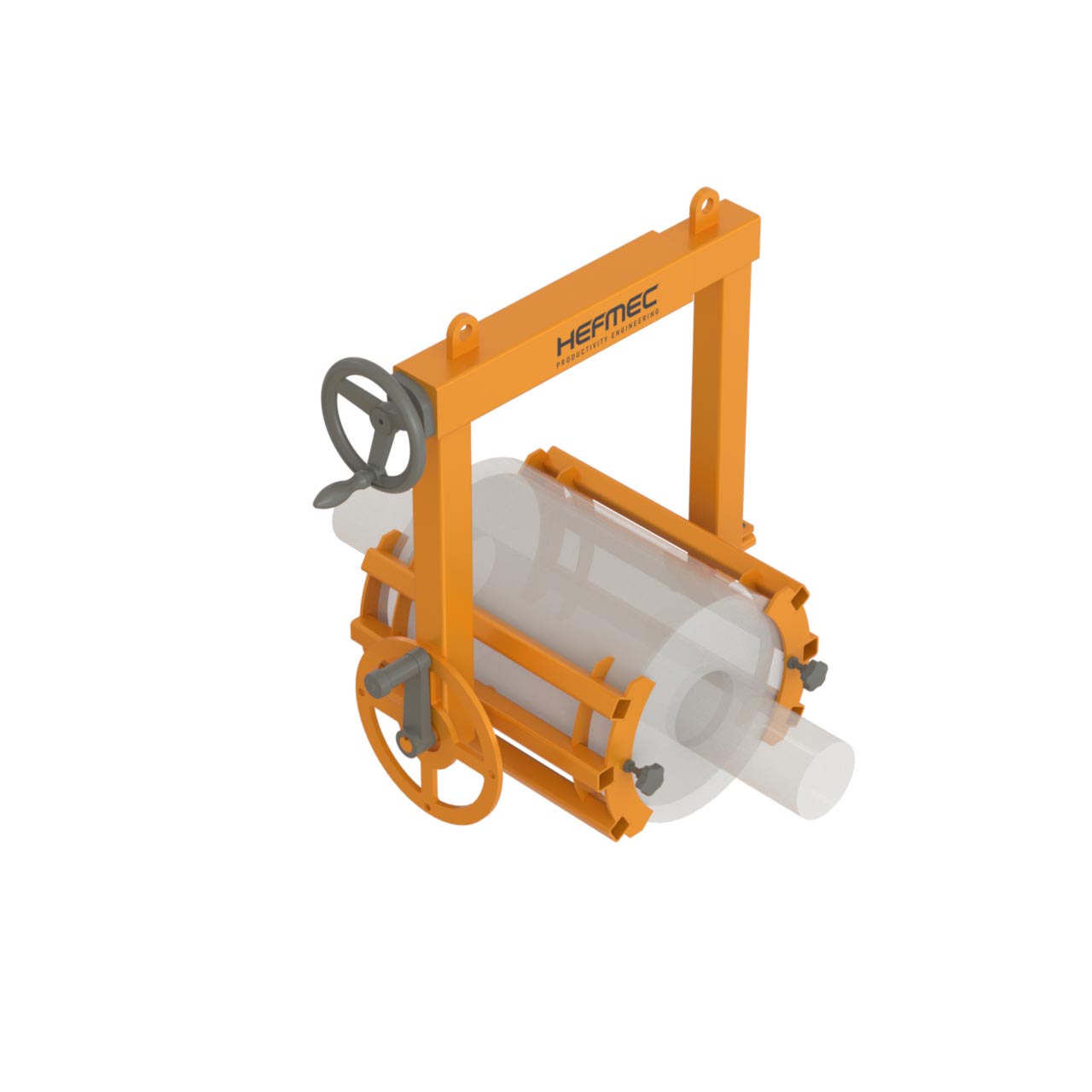

Clampy grabber

With clamp-type grippers, lifting and turning of round objects can be done quickly and safely with a single clamp. The clamped grip allows the other side of the workpiece to be machined or clamped. The customer saves on cycle time and production costs. We have supplied clamp-like grippers for products of different sizes, such as spool bearings and bearings.

We supply clamp-on grippers also for hygienic and GMP environments, meeting FDA requirements.

NOTE: The products are examples of products we tailor for our customers. Hefmec designs each lifting accessory according to the customer’s needs.

Product description

Clamp-type grippers can be used to grip a circular object. In addition to barrel-shaped objects, the tool can also be used to pick up perfectly round objects. During the lifting operation, the piece can be rotated infinitely, while it is attached to the gripper at all times. The stepless turning allows, for example, the contents of the piece to be lifted to be poured in a single operation. After turning, the workpiece can be placed on a machine tool, for example, after which the lifting accessory can be removed and taken away.

The advantage of clamp-on grippers is that lifting and turning can be done steplessly and safely with a single piece of clamping. During lifting, the load can be clamped or machined from the other side. The customer saves on phase time and therefore also on production costs.

- We supply CE-marked lifting equipment with turnkey delivery

- The products we supply have a one-year guarantee

- The guarantee covers defects in the design, materials and workmanship of load-bearing structures during their design lifetime.

- The lifting equipment complies with the Machinery Directive or the national regulations of the country of destination.

- Lifting equipment is supplied with an instruction and maintenance manual, a declaration of conformity and an inspection report.

Order a product

Contact Mikael Ekholm, Product Manager, and we will design a lifting aid that meets your needs.

MIKAEL EKHOLM

+358 50 434 3827

mikael.ekholm (at) hefmec.fi